IShielded Metal Arc Welding (efinyeziweyo njenge-SMAW).Umgaqo ngulo: i-arc yenziwa phakathi kwe-electrode edibeneyo kunye nesiseko sesinyithi, kunye nendlela ye-welding esebenzisa ukushisa kwe-arc ukunyibilikisa i-electrode kunye nesiseko sesinyithi.Uluhlu lwangaphandle lwe-electrode lugutyungelwe nge-welding flux kwaye luyancibilika xa lubonakaliswe ukushisa, olunemisebenzi yokuzinzisa i-arc, ukwenza i-slag, i-deoxidizing, kunye nokucoca.Ngenxa yokuba ifuna izixhobo ezilula kunye nokusebenza okuguquguqukayo, inokudityaniswa ngokulula kwi-welds eyenziwe ngezikhundla ezahlukeneyo kunye namalungu ahlukeneyo esithubeni.Ngoko ke, isasetyenziswa ngokubanzi ngoku.

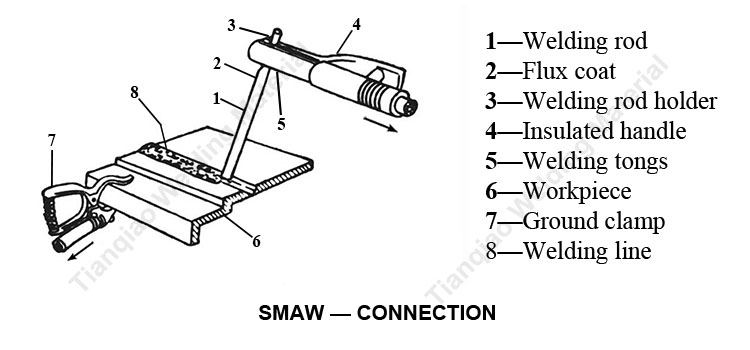

Umzobo 1: I-Shielded Metal Arc Welding-connection

I-arc welding ye-manual iboniswe kumzobo:

Ngaphambi kwe-welding, qhagamshela i-welding workpiece kunye ne-welding tongs kwiipali ezimbini zomatshini we-welding wombane kwaye udibanise intonga ye-welding nge-tongs.Ngethuba le-welding, intonga ye-welding kunye ne-workpiece idibanisa ngokukhawuleza, yenza isiphaluka esifutshane, kwaye emva koko ihlukaniswe ngumgama othile (malunga ne-2-4mm), kwaye i-arc iyatshiswa.

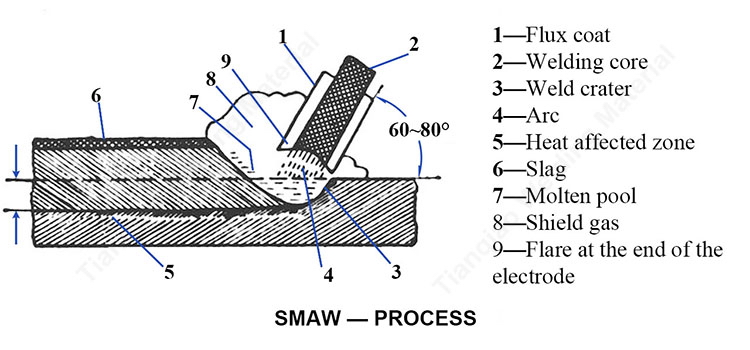

Umzobo 2: I-Shielded Metal Arc Welding-nkqubo

Umsebenzi ophantsi kwe-arc uyanyibilika ngoko nangoko ukwenza ichibi elinyibilikisiweyo le-semi-oval.Emva kokuba i-electrode coating iyancibilika, inxalenye yayo iba yigesi ejikeleze i-arc ukuyihlukanisa emoyeni, ngaloo ndlela ikhusela isinyithi esilulwelo kwi-oksijini kunye ne-nitrogen;inxalenye yawo iba yi-slag etyhidiweyo, okanye itshizwe kwidama elinyibilikisiweyo lodwa, okanye inyibilikiswe ngombindi

Kwi-arc kunye ne-pool etyhidiweyo, isinyithi se-liquid, i-slag kunye ne-arc gas iya kuba neenguqu ezithile zomzimba kunye neekhemikhali kunye nomnye, njengokutshatyalaliswa kwegesi kwisinyithi se-liquid kunye ne-oxidation-reduction reaction.Irhasi kunye ne-slag kwidama elityhidiweyo lidada ngenxa yobunzima bayo obulula.Xa i-arc isusiwe, ukushisa kwehla kwaye isinyithi kunye ne-slag iya kuqinisa enye emva komnye.Ngale ndlela, iziqwenga ezibini zetsimbi zidityaniswa yintsimbi enyibilikisiweyo kunye nekristalisiweyo.Ngenxa yokuba ukucutheka kwe-slag kuyahluke kwintsimbi, kuya kutyibilika kwiqokobhe le-slag kunye nomda wesinyithi, kwaye iqokobhe le-slag linokuwa ngokuzenzekelayo, okanye liwe emva kokuba libethelwe, kunye nentsimbi ye-weld seam enezikali zeentlanzi. inokuvezwa.

Isixhobo esiphambili se-arc welding manual ngumatshini we-welding wombane.Umatshini wokuwelda wombane ngumthombo wamandla ovelisa i-arc ye-welding, kwaye kukho iindidi ezimbini ze-AC kunye ne-DC.Okwangoku, kukho iintlobo ezininzi zoomatshini bokuwelda bombane abaveliswa eTshayina, abanokwahlulwa babe ngoomatshini bokuwelda bombane be-AC kunye noomatshini bokuwelda bombane be-DC ngokwesakhiwo sabo.

Kukho iindlela ezimbini ezahlukeneyo zoqhagamshelo koomatshini bokuwelda beDC.Xa i-electrode ixhunywe kwi-electrode engafanelekanga kwaye i-workpiece ixhunyiwe kwi-electrode efanelekileyo, yindlela yokudibanisa efanelekileyo;ngokuchaseneyo yindlela yoqhagamshelo ebuyela umva.Ngokubanzi, xa welding nge alkaline low-hydrogen electrode (ezifanaE7018, E7016), ukwenzela ukuba i-arc ivuthe ngokuzinzileyo, kuchazwe ukuba kusetyenziswe indlela yokudibanisa i-DC reverse;xa usebenzisa i-asidi electrode (efanaE6013, J422) ukuwelda iipleyiti zentsimbi ezishinyeneyo, indlela yoqhagamshelo lwangaphambili isetyenziswa, kuba indawo ye-anode Iqondo lobushushu liphezulu kunecathode, kwaye indlela yoqhagamshelo lwangaphambili inokufumana ubunzulu bokungena okukhulu;xa udibanisa iipleyiti zentsimbi ezibhityileyo kunye neentsimbi ezingenayo i-ferrous, indlela yokudibanisa i-reverse iyasetyenziswa.Xa i-welding kunye ne-alternating current, ekubeni i-polarity itshintsha ngokuhlukileyo, akukho mfuneko yokukhetha uxhulumaniso lwe-polarity.

Izinto zokuwelda ze welding manual yi welding rod yombane, equlathe intsimbi engundoqo kunye nokwaleka ngaphandle kombindi wentsimbi (Kwakhona bonaUkuqulunqwa kwe-electrode ye-welding).

Welding core

Indima yentsimbi yentsimbi (i-welding core) iyinhloko ukuqhuba umbane kunye nokwenza isinyithi esidiphothiweyo kunye nokubunjwa okuthile ekupheleni kwe-electrode.Isiseko se-welding sinokwenziwa ngeentsimbi ezahlukeneyo.Ukubunjwa kwe-welding core kuchaphazela ngokuthe ngqo ukubunjwa kunye nokusebenza kwetsimbi egciniweyo.Ngoko ke, i-welding core iyadingeka ukunciphisa umxholo wezinto ezinobungozi.Ukongeza kokukhawulela i-S kunye ne-P, ezinye iintonga ze-welding ziye zafuna ukuba i-welding core ilawule njenge, i-Sb, i-Sn kunye nezinye izinto.

Umzobo 3: Tianqiao welding electrode E6013

Idyasi yeFlux

I-Electrode coating ingabizwa ngokuba yipeyinti.Injongo ephambili yokuyigubungela kwi-core kukuququzelela ukusebenza kwe-welding kunye nokuqinisekisa ukuba isinyithi esidiphothiweyo sinokubunjwa kunye nokusebenza okuthile.Iingubo ze-Electrode zinokuxutywa kunye namakhulu omgubo wezinto eziphathekayo ezifana ne-oxides, i-carbonates, i-silicates, i-organics, i-fluorides, i-ferroalloys kunye neemveliso zemichiza ngokomlinganiselo othile wefomula.Izinto ezahlukeneyo eziluhlaza zinokwahlulwa zibe zezi ndidi zilandelayo ngokwendima yazo kwi-electrode coating:

1. I-Stabilizer yenza i-electrode ibe lula ukuqala i-arc kwaye inokugcina i-arc ivutha ngokuzinzileyo ngexesha lenkqubo ye-welding.Nayiphi na into ekulula ukuyenza ionize inokuzinzisa i-arc.Ngokuqhelekileyo, iikhompawundi zesinyithi zealkali kunye nesinyithi se-alkaline yomhlaba, njenge-potassium carbonate, i-sodium carbonate, i-marble, njl., iyasetyenziswa.

2. I-ejenti yokwenza i-slag inokwenza i-slag etyhidiweyo kunye neempawu ezithile zomzimba kunye neekhemikhali ngexesha le-welding, igubungele ubuso bentsimbi etyhidiweyo, ikhusela i-pool ye-welding kunye nokuphucula imilo ye-weld.

3. I-Deoxidizer ngokusebenzisa i-metallurgical chemical reaction kwi-welding process ukunciphisa umxholo we-oksijini kwi-weld metal kunye nokuphucula iimpawu ze-mechanical weld.Ii-deoxidizers eziphambili yi-ferromanganese, i-ferrosilicon, kunye ne-ferro-titanium.

4. I-arhente yokuvelisa igesi inokwahlula kwaye ikhulule igesi phantsi kwesenzo se-arc ukushisa okuphezulu ukukhusela i-arc kunye ne-pool etyhidiweyo kunye nokukhusela ukungena kwe-oksijini kunye ne-nitrogen emoyeni ojikelezayo.

5. I-agent ye-alloying Isetyenziselwa ukuhlawulela ukutshiswa kwezinto ezidibeneyo kunye nokutshintshwa kwezinto ezidibeneyo kwi-weld ngexesha lenkqubo ye-welding ukuze kuqinisekiswe ukuba i-weld metal ifumana ukubunjwa kweekhemikhali eziyimfuneko kunye nokusebenza.

6. I-Plasticizing Lubricant Yandisa iplastiki, i-slippage kunye ne-fluidity ye-powder yokugqoka kwi-welding rod pressing process ukuphucula umgangatho woxinzelelo lwentonga ye-welding kunye nokunciphisa i-eccentricity.

7. I-Adhesives Yenza i-powder yokugqoka ibe ne-viscosity ethile ngexesha lenkqubo yokuxinzelela, inokubambelela ngokuqinileyo kunye ne-welding core, kwaye yenza ukuba i-welding intonga ibe namandla athile emva kokumisa.

Ixesha lokuposa: Jul-27-2021