I-Argon tungsten arc welding isebenzisa i-argon njengegesi ekhuselayo ukutshisa kwaye inyibilikise i-welding material ngokwayo (iphinde inyibilike xa isinyithi sokuzalisa sidityaniswa) ngokusebenzisa i-arc eyenziwa phakathi kwe-electrode ye-tungsten kunye nomzimba we-weld, kwaye emva koko yenza ukuwelda. ye weld metal Indlela.Itungsten electrode,i-weld pool, i-arc kunye nommandla we-joint seam eshushulwe yi-arc ikhuselwe ekungcoleni kwe-atmospheric yi-argon flow.

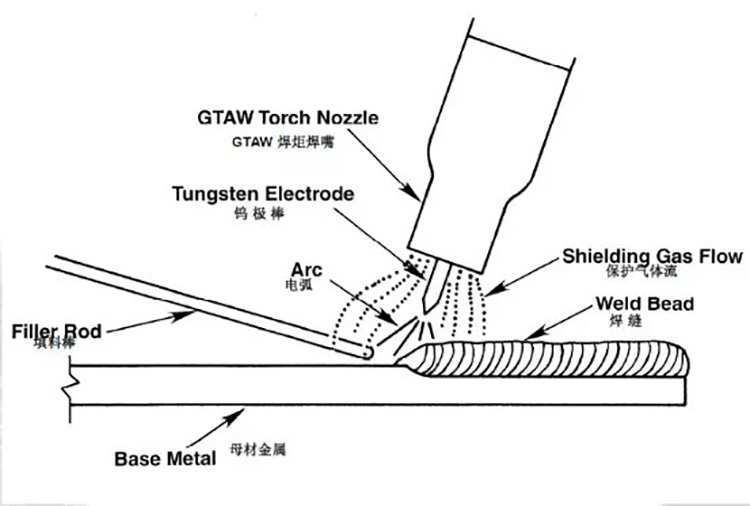

Ngexesha le-argon arc welding, izikhundla ezihambelanayo ze-torch, i-filler metal kunye ne-weldment njengoko kuboniswe kumfanekiso ongezantsi: ubude be-arc ngokuqhelekileyo bu-1 ~ 1.5 amaxesha ububanzi be-electrode ye-tungsten.Xa i-welding imisiwe, i-filler metal iqala ikhutshwe kwi-pool etyhidiweyo (i-metal filler yongezwa ngokobunzima be-weldment), kwaye isiphelo esishushu sisafuna ukuhlala phantsi kokhuseleko lokuhamba kwe-argon ukukhusela i-oxidation yayo. .

1. Itotshi yokuwelda (itotshi)

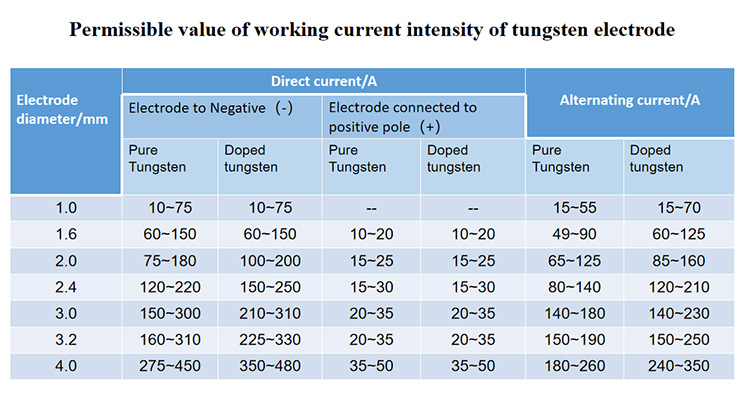

Ukongeza ekubambeni i-electrode ye-tungsten kunye nokuhambisa i-welding current, i-argon tungsten arc welding torch (ekwaziwa ngokuba yi-welding torch) nayo ifuna ukutshiza igesi yokukhusela.Imipu ye-welding ephezulu yangoku kufuneka isebenzise izibhamu ezifakwe emanzini ezipholileyo kwi-welding yexesha elide.Ngoko ke, ukusetyenziswa ngokuchanekileyo kunye nokukhuselwa kwetotshi ye-welding kubaluleke kakhulu.Umthamo wangoku weTungsten electrode (A) uboniswe kwitheyibhile engezantsi.

2. Indlela yegesi

Indlela yegesi yenziwe nge-argon cylinder yokunciphisa ivalve, i-flow meter, ithumbu kunye ne-electromagnetic gas valve (ngaphakathi kumatshini wokuwelda).I-valve yokunciphisa uxinzelelo isetyenziselwa ukunciphisa uxinzelelo kunye nokulungelelanisa uxinzelelo lwegesi yokukhusela.I-flowmeter isetyenziselwa ukulinganisa kunye nokulungelelanisa ukuhamba kwegesi ekhuselayo.Oomatshini be-welding ye-Argon arc bahlala besebenzisa i-flowmeter edibeneyo yokunciphisa i-decompression, efanelekileyo kwaye inokwethenjelwa ukuyisebenzisa.

Ngexesha le-argon arc welding, imfuno yokucoceka kwegesi ye-argon kukuba i-chromium-nickel insimbi engenasici kufuneka ibe ≥99.7%, kwaye isinyithi esichasayo kufuneka sibe ≥99.98%.

(1) I-Argon yigesi ye-inert, kwaye akulula ukusabela kunye nezinye izinto zetsimbi kunye neegesi.Ngaphezu koko, ngenxa yempembelelo yokupholisa ukuhamba komoya, indawo echaphazelekayo yokushisa i-weld encinci kwaye i-deformation ye-weldment encinci.Yeyona gasi ikhuselayo yeargon tungsten arc welding.

(2) Argon ikakhulu isetyenziselwa ukukhusela ngokufanelekileyo ichibi elinyibilikisiweyo, ukuthintela umoya ekukhukuliseni ichibi elinyibilikisiweyo kwaye kubangele oxidation ngexesha lenkqubo welding, kwaye kwangaxeshanye ngempumelelo ukwahlula umoya kwindawo weld, ukuze indawo weld. ikhuselwe kunye nokusebenza kwe-welding kuphuculwe.

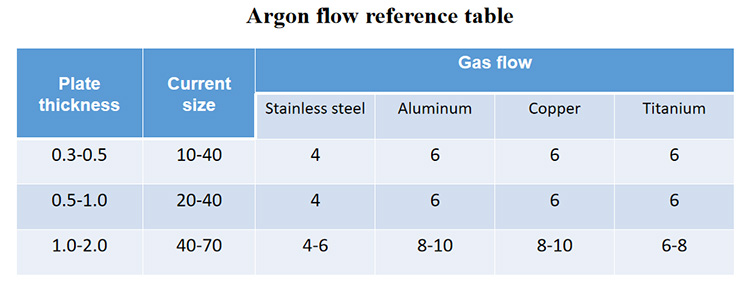

(3) Indlela yokulungelelanisa inqunywe ngokwezinto zetsimbi eziza kuxutywa, ubungakanani bangoku, kunye nendlela ye-welding: inkulu yangoku, igesi enkulu yokukhusela.Kwizinto ezisebenzayo zezinto, igesi ekhuselayo kufuneka iqiniswe ukuze inyuse izinga lokuhamba.

3. Iiparamitha zokucaciswa

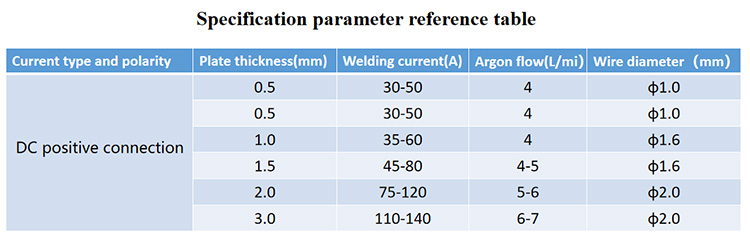

Iiparamitha ezisemgangathweni ze-argon tungsten arc welding ikakhulu ibandakanya yangoku, i-voltage, isantya se-welding, kunye nokuhamba kwegesi ye-argon, kwaye amaxabiso abo anxulumene nohlobo lwezinto ezidityanisiweyo, ubukhulu bepleyiti kunye nohlobo oludibeneyo.

Iiparamitha eziseleyo ezifana nobude be-electrode ye-tungsten ephuma kumbhobho ngokuqhelekileyo i-1-2 ngokuphindwe kabini ububanzi be-electrode ye-tungsten, umgama phakathi kwe-electrode ye-tungsten kunye ne-weldment (ubude be-arc) ngokubanzi buyi-1.5 amaxesha ububanzi be-tungsten. i-electrode, kunye nobukhulu bombhobho buchongwa emva kokuba ixabiso langoku le-welding lichongiwe.Khetha kwakhona.

Imiba yokuwelda ngokubanzi yentsimbi engenastainless i-argon arc yile ilandelayo:

4. Ukucoca phambi kwe-welding

I-Tungsten argon welding ye-arc inomdla kakhulu kungcoliseko lwe-weldment kunye ne-filler surface metal, ngoko ke igrisi, i-coating, i-lubricant kunye nefilimu ye-oxide kumphezulu we-weldment kufuneka isuswe ngaphambi kokuba ifakwe.

5. Iteknoloji yokhuseleko

Abaqhubi be-argon tungsten arc welding kufuneka banxibe iimaski zentloko, iiglavu, iimpahla zokusebenza, kunye nezihlangu zokusebenza ukuphepha ukutsha kwe-ultraviolet kunye ne-infrared kwi-arc.Oomatshini bokuwelda be-Steyr tungsten argon baxhotyiswe ngeziqalo ze-arc zesantya esiphezulu.Nangona i-low-frequency high-frequency high-voltage umbane akayi kuthusa umqhubi, xa ukusebenza kwe-insulation kungalunganga, umbane ophezulu we-high-frequency uya kutshisa ulusu lwesandla somqhubi , kwaye kunzima ukunyanga, ngoko ukusebenza kwe-insulation Umqheba we-welding kufuneka uhlolwe rhoqo.Ngexesha le-argon tungsten arc welding, umoya wokungenisa umoya kwindawo ye-welding kufuneka uphuculwe.

Phawula: Into ephambili kukuba ube nobuchule kunye nobuqili.Ubukhulu bebhodi, ixesha lokucofa, kunye nekhoyo ngoku zonke zihambelana, kwaye kufuneka basebenzisane omnye nomnye.

Xa i-welding, musa ukukhomba inqaku lenaliti kwindawo yokudibanisa ekuqaleni, kwaye uyibethe ingenanto kuqala ukukhupha umoya kumbhobho, ukwenzela ukuba i-welding ayiyi kuqhuma kwaye ayiyi kuba namabala amnyama.Imizuzwana embalwa, ngale ndlela, insimbi engenasici ikhuselwe yi-argon gas ngexesha lokupholisa, ngoko ayiyi kuba mnyama, kwaye namanzi okuhlamba kunye nephepha lokupolisha ligcinwa.Oku kungasetyenziselwa kuphela ukuwelda indawo.Ukuba urhuqa i-welding umgama omde, akukho ndlela.Ibhodi ngokuqinisekileyo iya kutshintsha umbala.Kufuneka ulinde ukupolisha kunye nokucoca.

Ixesha lokuposa: May-16-2023