I-electrode ye-welding yile a isinyithiintonga enyibilikisiweyo kwaye izaliswe ngokudityaniswa kwesiqwenga somsebenzi ngexesha le-welding yegesi okanye iwelding yombane. Izinto ze-electrode zihlala zifana nezinto zokwenza umsebenzi.

Apha siza kuqonda ukuba i-welding electrode yenziwe njani:

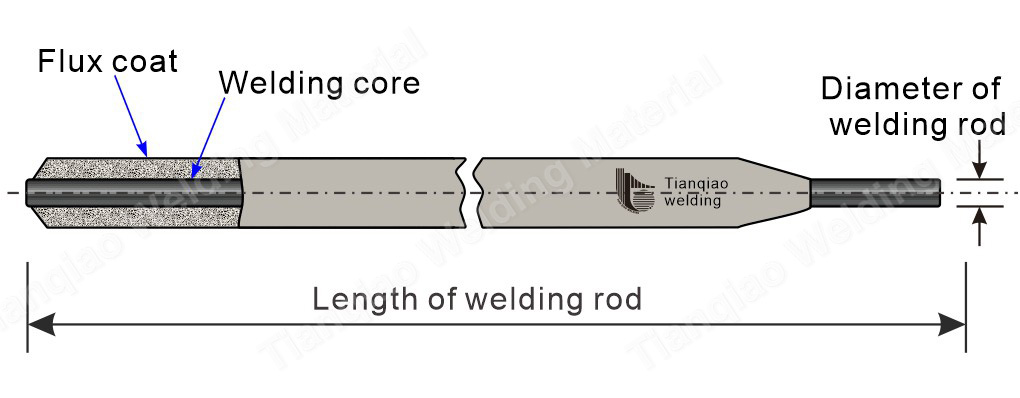

Umzobo 1 Ulwakhiwo lwe-Tianqiao welding electrode

I-electrode ye-welding yi-electrode enyibilikiweyo egutyungelwe ukutyabeka i-arc welding yentonga ye-welding. Iqulethwe yokwaleka kunye nomxholo we-welding.

Isiseko sesinyithi esigutyungelwe ngokugquma kwintonga ye-welding sibizwa ngokuba yi core ukuwelda. Isiseko se-welding ngokubanzi yintsimbi yentsimbi enobude obuthile kunye nobubanzi.

Umzobo 2 Isiseko se-Tianqiao welding electrode

Imisebenzi emibini yengundoqo

1. Yenza i-welding yangoku kwaye wenze i-arc ukuguqula amandla ombane abe bubushushu.

2. Isiseko se-welding ngokwaso siyanyibilika njengesinyithi sokugcwalisa kunye nefyuzi yentsimbi engamanzi ukwenza i-weld. Xa ukuwelda nge-electrode, isinyithi esiyintloko sithatha inxalenye yesinyithi sonke. Ke ngoko, ukwenziwa kweekhemikhali kwesiseko se-weld kuchaphazela ngokuthe ngqo umgangatho we-weld. Ke ngoko, ucingo lwentsimbi olusetyenziswe njengombindi we-electrode lunophawu lwalo kunye nolwakhiwo oluchazwe ngokwahlukeneyo.

Ukutyabeka kwe-electrodeibhekisa kumaleko wokutyabeka asetyenziswe kumphezulu wesiseko se-welding. Ukutyabeka kubolile kwaye kuyanyibilika kwinkqubo yokunyibilika ukwenza igesi kunye ne-slag, edlala indima kukhuseleko loomatshini, unyango lwe-metallurgical, kunye nokuphuculwa kwenkqubo yokusebenza.

Umzobo 3 Ukwaleka kwe-Tianqiao welding electrode

Ukwakhiwa kwengubo kubandakanya: izimbiwa (ezinjengeemabhile, i-fluorspar, njl. iimveliso zeekhemikhali (ezinje nge-titanium dioxide, iglasi yamanzi, njl.). Ukutyabeka i-Electrode yinto ebalulekileyo ekumiseleni umgangatho we welds.

Eyona misebenzi iphambili yokutyabeka kwinkqubo ye-welding

1. Ukuphucula ukuzinza kokutsha komlilo:

I-electrode engafakwanga akukho lula ukuyicima i-arc. Nokuba ithe yalayishwa, ayinakutshisa ungazinzanga.

2. Khusela iphuli:

Ngexesha lenkqubo yokuwelda, ioksijini, i-nitrogen kunye nomphunga emanzini zingena ngaphakathi kumthungo we-weld, oya kuthi ube nefuthe elibi kumthungo we-weld. Hayi kuphela pores, kodwa ukunciphisa iipropati ngoomatshini weld, nkqu ebangela iintanda. Emva kokuba isinyibilikisi se-electrode sinyibilikile, isixa esikhulu segesi senziwe sigubungele i-arc kunye nephuli etyhidiweyo, eya kuthi inciphise unxibelelwano phakathi kwesinyithi esityhidiweyo kunye nomoya. Xa iwelding ipholile, ukutyabeka okunyibilikileyo kwenza ungqimba lwe-slag, egubungela umphezulu we-weld, ikhusela isinyithi se-weld kwaye siyipholisa kancinci, ukunciphisa amathuba okuphuma.

Okwesithathu, ukuqinisekisa ukuba i-weld iyasuswa kunye ne-desulfurized kunye ne-phosphorus ukungcola

Nangona ukhuselo lwenziwa ngexesha lenkqubo ye-welding, kusenokwenzeka ukuba inani elincinci leoksijini liya kungena echibini elinyibilikisiweyo ukuze lidibanise izinto zentsimbi kunye ne-alloy, zitshise izinto ze-alloy, kunye nokunciphisa umgangatho we-weld. Ke ngoko, kufuneka ukongeze iarhente yokunciphisa (enje nge manganese, i-silicon, i-titanium, i-aluminium, njl.

4. Izinto zokufakelwa kokufakelwa kwesinyithi:

Ngenxa yesiphumo sobushushu obuphezulu be-arc, izinto ezinyibilikisayo zentsimbi zentsimbi ziya kunyuka zize zitshiswe, nto leyo eya kuthi inciphise iipropathi zoomatshini zentsimbi. Ke ngoko, kufanelekile ukongeza izinto ezifanelekileyo zokufakelwa kwesinyithi ngokudibanisa ukuhlawulela ilahleko etshisiweyo yezinto ze-alloy kunye nokuqinisekisa okanye ukuphucula iipropathi zoomatshini zentsimbi. Ngokudibanisa ezinye i-alloy steels, kuyafuneka ukuba ungene kwi-weld ngokusebenzisa i-welding, ukuze isinyithi sisondele kwisinyithi sesiseko sesinyithi, kwaye iipropathi zoomatshini zinokufumana okanye zidlule isiseko sesinyithi.

Ukuphucula imveliso ye-welding kunye nokunciphisa ukusasazeka:

Ukutyabeka i-electrode kunesiphumo sokwandisa ithontsi kunye nokunciphisa ukusasazeka. Indawo yokunyibilika kwengubo ye-electrode iphantsi kancinci kunendawo yokuwelda engumbindi. Nangona kunjalo, kuba isiseko se-welding sisembindini we-arc kwaye iqondo lobushushu liphezulu kakhulu, isiseko se-welding siyanyibilika kuqala, kwaye ukutyabeka kuyanyibilika kamva. Kwangelo xesha, ukusukela oko ilahleko yesinyithi ebangelwe kukusasazeka incitshisiwe, ukungalingani kokufakwa kuyonyuswa, kunye nemveliso ye-welding nayo iphuculwe.

Ukubunjwa kwe-electrode ehambelana ne-welding:

Ngokumalunga nexabiso lobundlongondlongo, siyakholelwa ukuba uyakukhangela kude nakubanzi kuyo nantoni na enokusibetha. Singatsho ngokulula ngokuqiniseka ngokupheleleyo ukuba kumgangatho ophezulu onje kumaxabiso asezantsi sesona sezantsi6013 Intonga yeWelding , Umatshini wokuTshisela iMangalam , Ukujongana Nzima I-Welding ElectrodeUmsebenzi wethu "kukubonelela ngeemveliso ezinokuthenjwa kunye namaxabiso afanelekileyo". Samkela abathengi kuzo zonke iimbombo zehlabathi ukuba banxibelelane nathi kubudlelane beshishini kwixesha elizayo kunye nokufezekisa impumelelo efanayo!