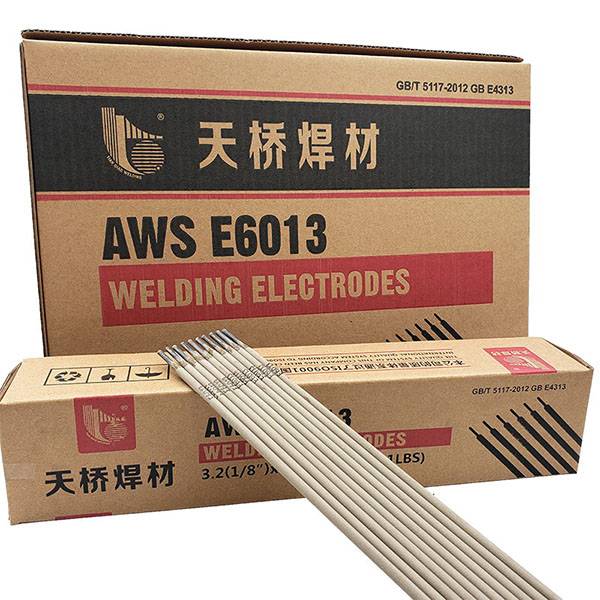

Umgubo wokuwelda: E6013

Usetyenziso:

I-E6013 ye-welding powder yokwenza i-electrode ye-welding, eluhlobo lwe-carbon steel electrode kunye ne-iron powder titania uhlobo lokutyabeka.U-AC DC.I-welding yendawo yonke.Inomsebenzi obalaseleyo we-welding kwaye iphantse yangena-spatter.Inokuvutha kwakhona okulula, ukuchithwa kakuhle kwe-slag, ukubonakala kwe-welding egudileyo.Ibakala eliqhelekileyo kunye nenqanaba le-rutile onokuthi ukhethe.

Iimbonakalo:

1.Uqhankqalazo oluKhawulezayo & Ukubetha ngokulula kunye nokususwa ngokulula kwe-slag

2.Intsebenzo ye-arc ezinzileyo kunye nokuphazamiseka okuncinci kwe-arc

3.Inkangeleko egudileyo kwaye imenyezelayo & neempawu zoomatshini ezigqwesileyo

4. Ukusebenza okuphezulu kunye namaxabiso aphezulu empembelelo kwi -30c.

5. Amazinga aphezulu ediphozithi

6. Ukumelana nokuqhekeka okugqwesileyo kunye nokusebenza kwe-x-reyi

7. Ukupakisha: 300kgs ukupakisha ingxowa damproof;okanye njengoko ubufuna

Ingqalelo:

I-1.I-Electrode kufuneka ivunywe ngu-350-380℃ ngeyure eli-1 ngaphambi kwe-welding, yomisa i-electrode xa uyisebenzisa.

2. Umhlwa, ioli, amanzi kunye nezinye izinto ezingcolileyo ze-weld kufuneka zisuswe ngaphambi kokuba zifakwe.

3. Kufuneka usebenzise i-arc i-welding emfutshane, i-swings akufanele ibe nkulu kakhulu, i-welding ye-bead emxinwa ifanelekile.

4. Ukuthintela ukuvelisa i-arc porosity, i-arc plate kufuneka yamkelwe okanye isebenzise indlela yokubuyisela i-arc welding.

Ukuqulunqwa kwemichiza:

| Izinto | I-TiO2 | AL2O3 | SiO2 | Mn | CaO+MgO | I-Organic | Okunye |

| Esona siphumo | 42 | 4.5 | 28 | 9 | 10.5 | 4 | 2 |

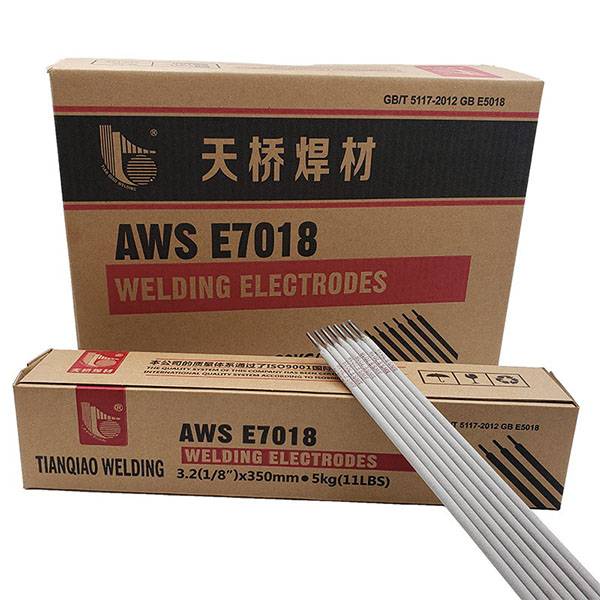

I-Welding electorde powder ye-E7018, E6011, E6010, E7024, njl.Pls uqhagamshelane nathi ngeenkcukacha ezithe vetshe.

Iimfuno zobugcisa benkqubo:

Iinxalenye ezibalulekileyo ze-welding kufuneka ziphawulwe ngokucacileyo ngokuhambelana nemimiselo efanelekileyo xa ulungiselela iinkcukacha zenkqubo ye-welding.

Ukudibanisa i-mold (i-assembly fixture) yeengxenye ezidibeneyo, ubungakanani be-welding shrinkage kufuneka buthathelwe ingqalelo.Kufuneka kuqinisekiswe ukuba ukunyamezela kwamacandelo adibeneyo kungaphakathi kweemfuno zokuyila.

Ngaphambi kokudibanisa, susa umhlwa, ioli, uthuli kunye nokufuma ngaphakathi kwe-25mm kumacala omabini e-weld.Kwiiwelds ezibalulekileyo zentsimbi ephantsi ye-alloy structural, isikali se-oxide kufuneka sisuswe.

I-gap yendibano kufuneka ilawulwe ngexesha lokuhlanganisa.Umsantsa we-welds we-butt yi-2 ~ 3mm, kwaye isithuba se-welds ye-fillet yi-0 ~ 2mm.Xa umsantsa wendawo umkhulu kakhulu, zama ukuwucutha ukuya kubungakanani obuchaziweyo.Akuvumelekanga ngokungqongqo ukongeza iifayili kwi-gap, kwaye ukudibanisa okunamandla akuvumelekanga ukunciphisa uxinzelelo olushiyekileyo kumacandelo adibeneyo.

Izinto zokudibanisa kunye neeparitha zenkqubo ezisetyenziswe kwi-welding ye-tack ye-welding ziya kufana neemfuneko ze-weld ezisemthethweni.

Imisebenzi ye-welding inokuqhutywa kuphela emva kokuba iinxalenye ze-welding zidlulile ukuhlolwa kwendibano.

Kwizinto ezintsha kunye neenkqubo ezintsha, iimvavanyo zenkqubo kufuneka zenziwe kwaye zingasetyenziswa kuphela emva kokuba zifanelekile.

I-welding slag kunye neziphene kwingcambu ye-weld kufuneka zisuswe ngaphambi kokuba zidibanise i-weld ebuyela umva ye-weld kunye nezinye i-welds ze-grooved.

I-Welding inokwenziwa kuphela emva kokucoca.

Ngaphambi kwe-welding, akuvumelekanga ukuqala ukutshisa i-arc kunye nokuvavanya ukulungiswa kwangoku kwindawo engeyiyo i-welding.Emva kwe-welding, umphezulu we-weld kufuneka ucocwe kwaye womiswe.

Umnatha, kwiindawo ezibalulekileyo ze-welding zeendawo ezibalulekileyo ze-welding, uphawu lwe-welder kufuneka luphawulwe kwindawo efanelekileyo emva kwe-welding.

Kwiipleyiti zetsimbi ezinobunzima be-0.3 ~ 4mm, iindlela ze-welding ezifana ne-gas metal arc welding okanye i-argon tungsten arc welding zisetyenziswa kakhulu.

Ukuze kufakwe i-welding of components dissimilar steel components, i-electrodes, iingcingo kunye ne-fluxes yezinga elifanayo lamandla kufuneka likhethwe.

Xa i-welding low-alloy structural steel, akukhuthazwa ukuba umise phakathi, kwaye uzame ukugqiba i-welding ngexesha elinye;ngexesha le-welding ye-multi-layer, i-joints phakathi kwe-maleko kufuneka iphazamise kwaye ubushushu phakathi kweeleya kufuneka ilawulwe phakathi kwe-250 ~ 300 ℃.Ngaphambi kokuba udibanise umaleko olandelayo we-welding seam, kufuneka icocwe.Jonga i-weld yomaleko ongaphezulu ukuqinisekisa ukuba akukho ziphene.