Imfuno yentsimbi kuluntu lwanamhlanje ikhula rhoqo.Ubomi bemihla ngemihla, izinto ezininzi zenziwe ngetsimbi, kwaye ezininzi isinyithi azikwazi ukuphoswa ngexesha elifanayo.Ngoko ke, kuyimfuneko ukusebenzisa i-welding yombane kwi-welding.Indima ye-electrode kwinkqubo ye-welding yombane ibaluleke kakhulu.

Intonga ye-welding inamandla kwaye iyancibilika kwiqondo lokushisa eliphezulu ngexesha le-arc welding, kwaye izalise amajoyina e-welding workpiece.Ngokuqhelekileyo, i-electrode ehambelanayo ikhethwa ngokwezinto eziphathekayo ze-welding workpiece.Intonga yokuwelda ingasetyenziselwa ukuwelda uhlobo olufanayo lwentsimbi okanye ukuwelda phakathi kweentsimbi ezahlukeneyo.

Ubume be-Welding Electrode

Ingundoqo yensimbi yangaphakathi yentonga ye-welding kunye nengubo yangaphandle ihlanganiswe.I-welding core yintsimbi yensimbi enobubanzi obuthile kunye nobude.Umsebenzi oyintloko we-welding core kukuqhuba okwangoku ukutshisa kunye nokunyibilika, kunye nokuzalisa kunye nokudibanisa i-workpiece.

Izinto ezingundoqo ezisetyenziselwa ukuwelda zinokwahlulwa ngokubanzi zibe yintsimbi yekhabhoni, intsimbi yealloy kunye nentsimbi engenasici.Nangona kunjalo, ukuze kuhlangatyezwane neemfuno ze-welding, kukho iimfuno ezikhethekileyo zezinto eziphathekayo kunye nentsimbi ye-welding core, kwaye kukho imimiselo engqongqo kumxholo wezinye izinto zetsimbi.Ngenxa yokuba ukubunjwa kwensimbi ye-welding core kuya kuchaphazela ngokuthe ngqo umgangatho we-weld.

Kuya kubakho umaleko wokugquma ngaphandle kwe-electrode, ebizwa ngokuba yi-flux coat.Idyasi yeFlux idlala indima ebalulekileyo.Ukuba i-welding core yombane isetyenziselwa ukuwelda ngokuthe ngqo i-workpiece, umoya kunye nezinye izinto ziya kungena kwintsimbi etyhidiweyo ye-welding core yombane, kwaye ukusabela kweekhemikhali kuya kwenzeka kwintsimbi etyhidiweyo ukuba ibangele ngokuthe ngqo i-weld.Iingxaki ezisemgangathweni ezifana neepores kunye neentanda ziya kuba nefuthe kumandla welding.Ingubo ye-Flux equlethe izinto ezikhethekileyo iya kubola kwaye inyibilike kwi-gas kunye ne-slag kumaqondo okushisa aphezulu, anokuthintela ngokufanelekileyo umoya ukuba ungene kwaye uphucule umgangatho we-welding.

Izithako zengubo ye-flux zibandakanya: i-hydrochloric acid, i-fluoride, i-carbonate, i-oxide, i-organic matter, i-iron alloy kunye nezinye iipilisi zeekhemikhali, njl., ezixutywe ngokwe-formula ethile.Ukubunjwa kweengubo zeentlobo ezahlukeneyo zokugqoka i-electrode nazo zihluke.

Kukho iintlobo ezintathu eziqhelekileyo, ezizezi, i-agent ye-slag, i-arhente evelisa igesi, kunye ne-deoxidizer.

I-agent ye-slag yi-compound enokukhusela isinyithi esityhidiweyo kwi-air ingress xa i-electrode inyibilika, ngaloo ndlela iphucula umgangatho we-welding.

I-agent evelisa igesi ikakhulu yenziwe ngestatshi kunye nomgubo womthi kunye nezinye izinto, ezinomlinganiselo othile wokunciphisa.

I-deoxidizer yenziwe nge-ferro-titanium kunye ne-ferromanganese.Ngokuqhelekileyo, ezo zinto zinokuphucula ukuxhathisa ukunxiba kunye nokuxhathisa ukubola kwesinyithi.

Ukongezelela, kukho ezinye iintlobo zeengubo kwi-electrode surface, kwaye ukubunjwa kunye nomlinganiselo wohlobo ngalunye luya kuhluka.

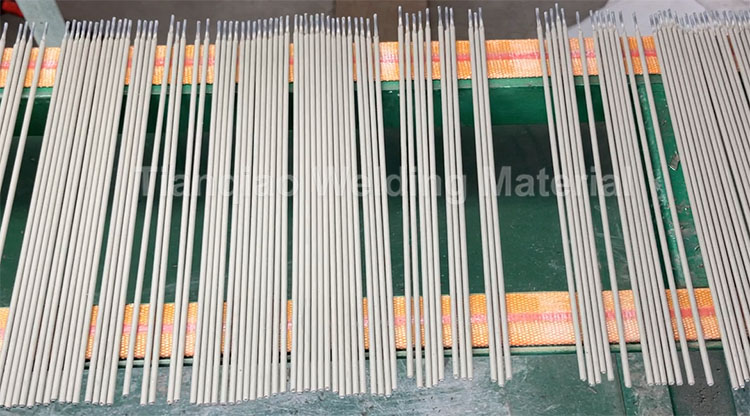

Inkqubo yokuvelisa i-electrode ye-welding

Inkqubo yokuvelisa intonga ye-welding kukuvelisa i-welding core kunye nokulungiselela ukugubungela ngokweemfuno zoyilo lwentonga ye-welding, kwaye usebenzise i-coating ngokulinganayo kwi-welding core ukuze ihlangabezane neemfuno zoyilo lwentonga ye-welding efanelekileyo.

Okokuqala, ibha yensimbi egobileyo ikhutshwe kwi-coiler, i-rust ebusweni bentsimbi yensimbi ikhutshwe kumatshini, kwaye iqondiswe.Umatshini usika ibha yentsimbi ukuya kubude be-electrode.

Emva koko, ukugqoka kufuneka kulungiswe phezu kwe-electrode.Izixhobo ezahlukahlukeneyo eziluhlaza zokugqoka zihluzwa ukuze zisuse ukungcola, kwaye zigalelwe kumatshini ngokomlinganiselo, kwaye i-binder yongezwa ngexesha elifanayo.Zonke izinto eziluhlaza eziwumgubo zixutywe ngokucokisekileyo kukuphazamiseka komatshini.

Beka umgubo oxutywe kwi-mold kwaye uyicinezele kwi-cylindrical cylinder kunye nomngxuma ojikelezayo phakathi.

Beka imigqomo emininzi ecinezelwe kumatshini, ubeke iintsimbi zokuwelda ngobunono kwizibuko lokutya komatshini, ii-cores ze-welding zingena kumatshini ukusuka kwi-port feed yomatshini ngokulandelelana, kunye ne-wedling cores idlula embindini wombhobho ngenxa ye-extrusion.Umatshini usasaza ngokulinganayo umgubo kwindawo edlulayo ukuze ube yityabeka.

Ngethuba lenkqubo yokugubungela intonga ye-welding, yonke i-welding core ifakwe ngoluhlu lwe-coating.Ukuze wenze i-electrode ibe lula ukuyibamba kwaye iqhube umbane, intloko kunye nomsila we-electrode kufuneka uphuculwe kwi-coating ukuze uveze i-welding core.

Emva kokusetyenziswa kwengubo, intloko yokugaya kunye nentonga ye-welding emva kokugaya umsila iya kulungelelaniswa ngokulinganayo kwisakhelo sentsimbi kwaye ithunyelwe kwi-oven ukuze yomiswe.

Ukuze ukwazi ukuhlukanisa ngokulula iinkcukacha kunye neemodeli ze-electrode, kuyimfuneko ukuprinta kwi-electrode.Xa intonga ye-welding ihamba kwibhanti yokuhambisa, i-electrode nganye iprintwa yi-roller yokushicilela irabha kwibhanti yokuhambisa.

Emva kokuba imodeli ye-welding iprintwe, intonga ye-welding inokupakishwa kwaye ithengiswe emva kokuphumelela ukuhlolwa.

I-electrode ye-welding ye-brand ye-Tianqiao inomsebenzi oncomekayo, umgangatho ozinzile, ukubunjwa kwe-welding ekhangayo, kunye nokususwa kwe-slag efanelekileyo, ukukwazi ukuxhathisa umhlwa, i-Stomata kunye nokuqhekeka, okulungileyo kunye nokuzinzileyo kwiimpawu zetsimbi ezigciniweyo.Iimpawu ze-Welding ze-Tianqiao zidibana nokwamkelwa ngokufudumeleyo kwabathengi ngenxa yomgangatho obalaseleyo, ukusebenza okubalaseleyo kunye nexabiso elikhuphisanayo.Cofa aphaukujonga ngakumbi malunga neemveliso zethu

Ixesha lokuposa: Sep-03-2021