Ukuhlolwa koMgangatho we-China Tc-Hse Flux yoBuyiselo kunye noMatshini wokutyisa (yekholamu kunye ne-boom njl.)

Yindlela entle yokuphucula ngakumbi izinto zethu kunye nokulungiswa.Injongo yethu iya kuba kukuphuhlisa izinto eziluncedo kubathengi ngokudibana okuphezulu kuHlolo loMgangatho weTshayina iTc-Hse Flux yoBuyiselo kunye noMatshini wokutyisa (yekholamu kunye ne-boom njl. njl.), Ngoku siye saseka unxibelelwano oluzinzileyo kunye nolude lwamashishini amancinci kunye nabathengi. ukusuka kuMntla Merika, eNtshona Yurophu, eAfrika, kuMzantsi Merika, kumazwe nemimandla engaphezulu lee kwama-60.

Yindlela entle yokuphucula ngakumbi izinto zethu kunye nokulungiswa.Injongo yethu iya kuba kukuphuhlisa izinto eziluncedo kubathengi ngokudibana okuphezuluUkubuyiselwa kweTshayina, Ukuwelda, Bayimodeli ehlala ixesha elide kwaye bakhuthaza ngempumelelo kwihlabathi liphela.Naphantsi kwazo naziphi na iimeko ukulahleka kwemisebenzi emikhulu ngexesha elikhawulezayo, kufanelekile ukuba ube nomgangatho olungileyo.Ikhokelwa ngumgaqo “woBuchule, uBuchule, iManyano kunye noTshintsho.Inkampani yenza iinzame ezimanyumnyezi ukwandisa urhwebo lwayo lwamazwe ngamazwe, ukunyusa inzuzo yenkampani kunye nokunyusa isikali sayo sokuthumela ngaphandle.Siqinisekile ukuba siza kuba nethemba eliqaqambileyo kwaye siza kusasazwa kwihlabathi liphela kwiminyaka ezayo.

Usetyenziso:

I-E6013 ye-welding powder yokwenza i-electrode ye-welding, eluhlobo lwe-carbon steel electrode kunye ne-iron powder titania uhlobo lokutyabeka.U-AC DC.I-welding yendawo yonke.Inomsebenzi obalaseleyo we-welding kwaye iphantse yangena-spatter.Inokutshisa kwakhona okulula, ukuchithwa kakuhle kwe-slag, ukubonakala kwe-welding egudileyo.Ibakala eliqhelekileyo kunye nenqanaba le-rutile onokuthi ukhethe.

Iimbonakalo:

1.Uqhankqalazo oluKhawulezayo & Ukubetha ngokulula kunye nokususwa ngokulula kwe-slag

2.Intsebenzo ye-arc ezinzileyo kunye nokuphazamiseka okuncinci kwe-arc

3.Inkangeleko egudileyo kwaye imenyezelayo & neempawu zoomatshini ezigqwesileyo

4. Ukusebenza okuphezulu kunye namaxabiso aphezulu empembelelo kwi -30c.

5. Amazinga aphezulu ediphozithi

6. Ukumelana nokuqhekeka okugqwesileyo kunye nokusebenza kwe-x-reyi

7. Ukupakisha: 300kgs ukupakisha ingxowa damproof;okanye njengoko ubufuna

Ingqalelo:

I-1.I-Electrode kufuneka ivunywe ngu-350-380℃ ngeyure eli-1 ngaphambi kwe-welding, yomisa i-electrode xa uyisebenzisa.

2. Umhlwa, ioli, amanzi kunye nezinye izinto ezingcolileyo ze-weld kufuneka zisuswe ngaphambi kokuba zifakwe.

3. Kufuneka usebenzise i-arc i-welding emfutshane, i-swings akufanele ibe nkulu kakhulu, i-welding ye-bead emxinwa ifanelekile.

4. Ukuthintela ukuvelisa i-arc porosity, i-arc plate kufuneka yamkelwe okanye isebenzise indlela yokubuyisela i-arc welding.

Ukuqulunqwa kwemichiza:

| Izinto | I-TiO2 | AL2O3 | SiO2 | Mn | CaO+MgO | Organic | Okunye |

| Esona siphumo | 42 | 4.5 | 28 | 9 | 10.5 | 4 | 2 |

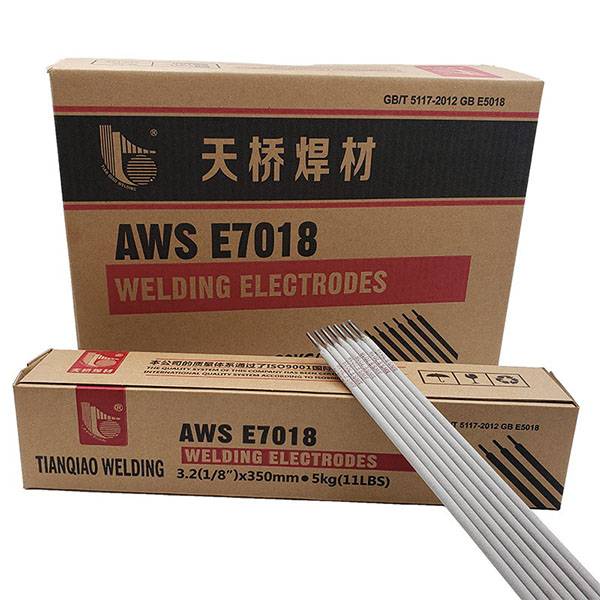

Ukuweldai-electrode powder ye-E7018, E6011, E6010, E7024, njl.Pls uqhagamshelane nathi ngeenkcukacha ezithe vetshe.

Iimfuno zobugcisa benkqubo:

Iinxalenye ezibalulekileyo ze-welding kufuneka ziphawulwe ngokucacileyo ngokuhambelana nemimiselo efanelekileyo xa ulungiselela iinkcukacha zenkqubo ye-welding.

Ukudibanisa i-mold (i-assembly fixture) yeengxenye ezidibeneyo, ubungakanani be-welding shrinkage kufuneka buthathelwe ingqalelo.Kufuneka kuqinisekiswe ukuba ukunyamezela kwamacandelo adibeneyo kungaphakathi kweemfuno zokuyila.

Ngaphambi kokudibanisa, susa umhlwa, ioli, uthuli kunye nokufuma ngaphakathi kwe-25mm kumacala omabini e-weld.Kwiiwelds ezibalulekileyo zentsimbi ephantsi ye-alloy structural, isikali se-oxide kufuneka sisuswe.

I-gap yendibano kufuneka ilawulwe ngexesha lokuhlanganisa.Umsantsa we-welds we-butt yi-2 ~ 3mm, kwaye isithuba se-welds ye-fillet yi-0 ~ 2mm.Xa umsantsa wendawo umkhulu kakhulu, zama ukuwucutha ukuya kubungakanani obuchaziweyo.Kunqatshelwe ngokungqongqo ukongeza iifayili kwi-gap, kwaye ukudibanisa okunamandla akuvumelekanga ukunciphisa uxinzelelo olushiyekileyo kumacandelo adibeneyo.

Izinto zokudibanisa kunye neeparitha zenkqubo ezisetyenziswe kwi-welding ye-tack ye-welding ziya kufana neemfuneko ze-weld ezisemthethweni.

Imisebenzi ye-welding inokuqhutywa kuphela emva kokuba iinxalenye ze-welding zidlulile ukuhlolwa kwendibano.

Kwizinto ezintsha kunye neenkqubo ezintsha, iimvavanyo zenkqubo kufuneka zenziwe kwaye zingasetyenziswa kuphela emva kokuba zifanelekile.

I-welding slag kunye neziphene kwingcambu ye-weld kufuneka zisuswe ngaphambi kokuba zidibanise i-weld ebuyela umva ye-weld kunye nezinye i-welds ze-grooved.

I-Welding inokwenziwa kuphela emva kokucoca.

Ngaphambi kwe-welding, akuvumelekanga ukuqala ukutshisa i-arc kunye nokuvavanya ukulungiswa kwangoku kwindawo engeyiyo i-welding.Emva kwe-welding, umphezulu we-weld kufuneka ucocwe kwaye womiswe.

Umnatha, kwiindawo ezibalulekileyo ze-welding zeendawo ezibalulekileyo ze-welding, uphawu lwe-welder kufuneka luphawulwe kwindawo efanelekileyo emva kwe-welding.

Kwiipleyiti zetsimbi ezinobunzima be-0.3 ~ 4mm, iindlela ze-welding ezifana ne-gas metal arc welding okanye i-argon tungsten arc welding zisetyenziswa kakhulu.

Ukuze kufakwe i-welding of components dissimilar steel components, i-electrodes, iingcingo kunye ne-fluxes yezinga elifanayo lamandla kufuneka likhethwe.

Xa i-welding low-alloy structural steel, akukhuthazwa ukuba umise phakathi, kwaye uzame ukugqiba i-welding ngexesha elinye;ngexesha le-welding ye-multi-layer, i-joints phakathi kwe-maleko kufuneka iphazamise kwaye ubushushu phakathi kweeleya kufuneka ilawulwe phakathi kwe-250 ~ 300 ℃.Ngaphambi kokuba udibanise umaleko olandelayo we-welding seam, kufuneka icocwe.Jonga i-weld yomgangatho ophezulu ukuze uqinisekise ukuba akukho ziphene.Yindlela enhle yokuphucula ngakumbi izinto zethu kunye nokulungiswa.Injongo yethu iya kuba kukuphuhlisa izinto eziluncedo kubathengi ngokudibana okuphezulu kuHlolo loMgangatho weTshayina iTc-Hse Flux yoBuyiselo kunye noMatshini wokutyisa (yekholamu kunye ne-boom njl. njl.), Ngoku siye saseka unxibelelwano oluzinzileyo kunye nolude lwamashishini amancinci kunye nabathengi. ukusuka kuMntla Merika, eNtshona Yurophu, eAfrika, kuMzantsi Merika, kumazwe nemimandla engaphezulu lee kwama-60.

Ukuhlolwa koMgangatho weUkubuyiselwa kweTshayina, Ukuwelda, Bayimodeli ehlala ixesha elide kunye nokukhuthaza ngempumelelo kwihlabathi liphela.Naphantsi kwazo naziphi na iimeko ukulahleka kwemisebenzi emikhulu ngexesha elikhawulezayo, kufanelekile ukuba ube nomgangatho olungileyo.Ikhokelwa ngumgaqo “woBuchule, uBuchule, iManyano kunye noTshintsho.Inkampani yenza iinzame ezimanyumnyezi ukwandisa urhwebo lwayo lwamazwe ngamazwe, ukunyusa inzuzo yenkampani kunye nokunyusa isikali sayo sokuthumela ngaphandle.Siqinisekile ukuba siza kuba nethemba eliqaqambileyo kwaye siza kusasazwa kwihlabathi liphela kwiminyaka ezayo.