I-Electrode arc welding yeyona ndlela isetyenziswa kakhulu kwimveliso yeshishini.Intsimbi ekufuneka idityaniswe yipali enye, kwaye i-electrode yenye ipali.Xa iipali ezimbini zisondelelene enye kwenye, i-arc yenziwa.Ubushushu obuveliswa yi-arc discharge (eyaziwa ngokuba yi-arc combustion) isetyenziselwa ukudibanisa i-electrode kunye ne-workpieces iyancibilika enye nenye kwaye yenze i-weld emva kokudibanisa, ukuze kufumaneke inkqubo ye-welding ngokudibanisa okunamandla.

Umzobo 1. Imbali ye-welding

Imbali emfutshane

Emva kovavanyo oluninzi lwe-welding kwangenkulungwane ye-19, indoda yaseNgesi egama linguWillard yafumana ilungelo elilodwa lomenzi wechiza lokuwelda ngo-1865. Wasebenzisa umsinga wombane ukudlula kwiziqwenga ezibini zentsimbi ukuze azidibanise ngempumelelo, kwaye malunga neminyaka engamashumi amabini kamva, umRashiya. ogama linguBernard wafumana ipatent yenkqubo ye-arc welding.Wagcina i-arc phakathi kwepali yekhabhoni kunye nezixhobo zokusebenza.Xa i-arc yayiqhutywa ngesandla ngokudibana kwezinto zokusebenza, izixhobo zokusebenza eziza kudityaniswa zadityaniswa kunye.Ngeminyaka yee-1890, isinyithi esiqinileyo saphuhliswa njenge-electrode, eyadliwa kwidama elityhidiweyo kwaye yaba yinxalenye yentsimbi ye-weld.Nangona kunjalo, ioksijini kunye nenitrogen emoyeni zenza iioksidi ezinobungozi kunye neenitridi kwintsimbi edibeneyo., Ngaloo ndlela kukhokelela kumgangatho ophantsi we-welding.

Ekuqaleni kwekhulu lama-20, ukubaluleka kokukhusela i-arc ukuphepha ukungena komoya kuye kwafezekiswa, kwaye ukusetyenziswa kobushushu be-arc ukubola i-coating kwi-electrode yesikhuselo segesi ekhuselayo yaba yindlela engcono kakhulu.Phakathi kwiminyaka yee-1920, i-electrode edibeneyo yaphuhliswa, eyaphucula kakhulu umgangatho wentsimbi edibeneyo.Kwangaxeshanye, inokuba lolona tshintsho lubalulekileyo lwe-arc welding.Isixhobo esiphambili kwinkqubo ye-welding ibandakanya umatshini we-welding wombane, i-welding tongs kunye nemaski yobuso.

Umzobo 2. Umgaqo we-welding

Umzobo 2. Umgaqo we-welding

Umgaqo

I-arc ye-welding inikwa amandla ngumthombo wamandla we-welding.Ngaphantsi kwesenzo sombane othile, into enamandla kunye nexesha elide lokukhutshwa kwenzeka phakathi kwe-electrode (kunye nokuphela kocingo lwe-welding okanye intonga ye-welding) kunye ne-workpiece.Undoqo we-arc welding yi-gas conduction, oko kukuthi, igesi engathathi hlangothi kwindawo apho i-arc ikhoyo ichithwa ibe yi-ion echajiwe kakuhle kunye nee-electron ezimbi phantsi kwesenzo sombane othile, obizwa ngokuba yi-ionization.La maqhekeza amabini ahlawuliweyo aqondiswe kwiipali ezimbini.Ukuhamba kwe-Directional kwenza irhasi yendawo iqhube umbane ukwenza i-arc.I-arc yombane iguqula amandla ombane abe bubushushu, obufudumeza kwaye bunyibilikise isinyithi ukwenza i-welded joint.

Emva kokuba i-arc ishukunyiswa ukuba "ivutha", inkqubo yokukhupha ngokwayo inokuvelisa iinqununu ezihlawulisiweyo ezifunekayo ukuze kugcinwe ukukhutshwa, okuyiyona nto yokuzimela.Kwaye inkqubo yokukhutshwa kwe-arc ine-voltage ephantsi, yangoku ephezulu, ubushushu obuphezulu kunye ne-luminescence enamandla.Ngale nkqubo, amandla ombane aguqulwa abe bubushushu, amandla omatshini kunye nokukhanya.I-Welding ikakhulu isebenzisa amandla ayo ashushu kunye noomatshini ukufezekisa injongo yokudibanisa isinyithi.

Ngexesha le-welding, i-arc iyatshisa phakathi kwentonga ye-welding kunye ne-welding workpieces, inyibilika i-workpieces kunye ne-electrode core ukwenza i-pool etyhidiweyo.Ngelo xesha, i-electrode coating nayo iyancibilika, kwaye i-chemical reaction yenzeke ukwenza i-slag kunye negesi, ekhusela ukuphela kwe-electrode, amaconsi, i-pool etyhidiweyo kunye ne-high-temperature weld metal.

Ukuhlelwa okuphambili

Iindlela eziqhelekileyo ze-arc welding ikakhulu ziquka i-Shielded Metal Arc Welding (SMAW), i-Submerged Arc Welding (SAW), i-Gas Tungsten Arc Weld (GTAW okanye i-TIG welding), i-Plasma Arc Welding (PAW) kunye ne-Gas Metal Arc Welding (GMAW, MIG okanye MAG welding). ) njl.

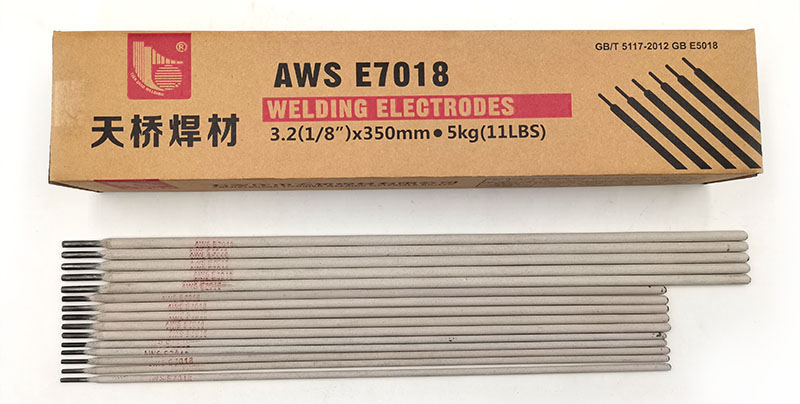

Umzobo 3. E7018 welding electrode

IShielded Metal Arc Welding (SMAW)

I-shielded metal arc welding isebenzisa i-electrode kunye ne-workpiece njenge-electrode ezimbini, kunye nobushushu kunye nokuvuthela kwamandla e-arc kusetyenziselwa ukunyibilika kwendawo yokusebenza ngexesha le-welding.Ngelo xesha, phantsi kwesenzo sobushushu be-arc, isiphelo se-electrode siyanyibilika ukuze senze i-droplet, kwaye i-workpiece iyancibilika ngokuyinxenye ukuze yenze i-oval pit ezaliswe yintsimbi engamanzi.Isinyithi esinyibilikisiweyo solwelo kunye nethontsi lesixhobo sokusebenzela zenza ichibi elityhidiweyo.Ngethuba lenkqubo ye-welding, i-coating kunye ne-non-metal yi-inclusions edibanisayo kwaye yenza into engeyiyo i-metallic egubungela umphezulu we-weld ngokusebenzisa utshintsho lweekhemikhali ezibizwa ngokuba yi-slag.Njengoko i-arc ihamba, idama elityhidiweyo liyaphola kwaye liqina ukwenza i-weld.Sine-electrode eyahlukeneyo ye-welding ye-SMAW, iimodeli ezidumileyo ziE6010, E6011, E6013, E7016, E7018, kwaye ngenxayenziwe ngentsimbi eshayinayo, Jula i-ayini, ubuso obuqinileyonjl.

Umzobo 4. I-arc welding ephantsi kwamanzi

Umzobo 4. I-arc welding ephantsi kwamanzi

Ukuwelda kweArc entywiliselweyo (SAW)

I-arc welding ephantsi kwamanzi yindlela apho i-arc itshisa phantsi kwe-flux layer ye-welding.I-electrode yensimbi esetyenziswe kwi-arc welding ephantsi kwamanzi ilucingo olungenanto oluzondliwa ngokuzenzekelayo ngaphandle kokuphazamiseka.Ngokuqhelekileyo, i-trolley ye-welding okanye ezinye izixhobo zomatshini kunye nombane zisetyenziselwa ukuqonda ukunyakaza okuzenzekelayo kwe-arc ngexesha lenkqubo ye-welding.I-arc ye-arc welding ephantsi kwamanzi iyatshisa phantsi kwe-granular flux.Ubushushu be-arc buyanyibilika kwaye bukhuphe amacandelo asebenze ngokuthe ngqo kwi-arc ye-workpiece, isiphelo socingo lwe-welding kunye ne-flux, kunye nomphunga wesinyithi kunye ne-flux e-evaporates ukwenza i-cavity evaliweyo ejikeleze i-arc.Tshiswa kulo mngxuma.Umgodi ujikelezwe yifilimu ye-slag eyenziwe nge-slag eveliswa yi-flux melting.Le filimu ye-slag ayigcini nje ukwahlula umoya ekudibaneni ne-arc kunye ne-pool etyhidiweyo, kodwa ikhusela i-arc ekuphumeni.I-welding wire eshushu kwaye inyibilikiswa yi-arc iwela ngendlela yamathontsi kwaye ixube kunye nesinyithi esinyibilikisiweyo sokwenza ichibi elityhidiweyo.I-slag encinci exineneyo idada kwidama elityhidiweyo.Ukongeza kokwahlulwa komatshini kunye nokukhuselwa kwesinyithi esityhidiweyo sechibi, i-slag etyhidiweyo iphinda iphinde iphinde iphinde iphinde iphendule ngesinyithi sechibi esinyibilikisiweyo ngexesha lenkqubo ye-welding, ngaloo ndlela ichaphazela ukubunjwa kweekhemikhali zentsimbi ye-weld.I-arc iqhubela phambili, kwaye i-pool yesinyithi etyhidiweyo iphola ngokuthe ngcembe kwaye ikhazimle ukwenza i-weld.Emva kokuba i-slag etyhidiweyo edada kwindawo ephezulu yechibi elinyibilikisiweyo iphola, i-slag crust iyakhiwa ukuze iqhubeke nokukhusela i-weld kwiqondo lokushisa eliphezulu kwaye ithintele ukuba i-oxidized.Sibonelela nge-flux ye-SAW,SJ101,SJ301,SJ302

Umzobo 5. Igesi yeTungsten Arc Weld-TIG

Umzobo 5. Igesi yeTungsten Arc Weld-TIG

Gas Tungsten Arc Weld/Tungsten Inert Gas Welding (GTAW okanye TIG)

I-TIG welding ibhekisela kwindlela ye-arc welding esebenzisa i-tungsten okanye i-tungsten alloy (i-thorium tungsten, i-cerium tungsten, njl.) njenge-electrode kunye ne-argon njengegesi yokukhusela, ebizwa ngokuba yi-TIG welding okanye i-GTAW welding.Ngexesha le-welding, isinyithi sokuzalisa sinokudibaniswa okanye singongezwa ngokwendlela ye-groove ye-weld kunye nokusebenza kwentsimbi ye-weld.Intsimbi yokuzalisa idla ngokudityaniswa ukusuka phambi kwe-arc.Ngenxa yobungcali be-aluminiyam-i-magnesium kunye nezixhobo zayo ze-alloy, i-AC tungsten arc welding iyafuneka kwi-welding, kunye ne-DC tungsten arc welding isetyenziselwa ezinye izinto zetsimbi.Ukuze ulawule igalelo lobushushu, i-pulsed argon tungsten arc welding isetyenziswa ngokubanzi.Ikakhulu isetyenziswa TIG iingcingo welding areAWS ER70S-6, I-ER80S-G,ER4043,ER5356,HS221kunye njl.

Umzobo 5. I-Plasma Arc Welding

Umzobo 5. I-Plasma Arc Welding

I-Plasma Arc Welding (PAW)

I-Plasma arc yindlela ekhethekileyo ye-arc.I-arc nayo i-tungsten okanye i-tungsten alloy (i-thorium tungsten, i-cerium tungsten, njl.) njenge-electrode ye-arc, isebenzisa i-argon njengegesi yokukhusela, kodwa i-electrode ye-tungsten ayiphumeleli ngaphandle kombhobho, kodwa ihoxise Ngaphakathi kwi-nozzle, i-nozzle. Ukupholiswa kwamanzi, okwakwaziwa ngokuba ngumphunga opholiswe ngamanzi.Igesi ye-inert ihlulwe ibe ngamacandelo amabini, enye inxalenye yigesi ekhutshwe phakathi kwe-electrode ye-tungsten kunye ne-nozzle epholile ngamanzi, ebizwa ngokuba yi-ion gas;enye inxalenye yigesi ekhutshwe phakathi kwe-nozzle epholileyo yamanzi kunye ne-hood ekhuselayo yegesi, ebizwa ngokuba yi-Shielding gas, isebenzisa i-plasma arc njengomthombo wokushisa we-welding, ukusika, ukutshiza, ukukhangela phezulu, njl.

Umfanekiso we-5 we-Metal-Inert ye-Gas Welding

Umfanekiso we-5 we-Metal-Inert ye-Gas Welding

I-Metal Inert Gas Welding (MIG)

Ukuwelda kwe-MIG kuthetha ukuba ucingo lwe-welding luthatha indawo ye-electrode ye-tungsten.I-wire welding ngokwayo enye yezibonda ze-arc, idlala indima yokuqhuba umbane kunye ne-arcing, kwaye ngexesha elifanayo njengento yokuzalisa, eqhubekayo inyibilika kwaye izaliswe kwi-weld phantsi kwesenzo se-arc.Igesi yokukhusela esetyenziswa ngokuqhelekileyo malunga ne-arc ingaba yigesi ye-inert Ar, igesi esebenzayo CO2, okanye i-Ar+CO2igesi edibeneyo.I-MIG welding esebenzisa i-Ar njengegesi ekhuselayo ibizwa ngokuba yi-MIG welding;I-MIG welding esebenzisa i-CO2njengoko igesi yokukhusela ibizwa ngokuba yiCO2ukuwelda.Ezona MIG zidumileyo ziAWS ER70S-6, I-ER80S-G.

Ixesha lokuposa: Aug-17-2021