Kukho iindidi ezintathu zokuwelda ngaphantsi kwamanzi: indlela eyomileyo, indlela emanzi kunye nendlela yokomisa inxalenye.

I-welding eyomileyo

Le yindlela apho igumbi elikhulu lomoya lisetyenziselwa ukugubungela i-weldment, kwaye i-welder yenza i-welding kwigumbi lomoya.Ekubeni i-welding yenziwa kwisigaba segesi esomileyo, ukhuseleko lwayo lungcono.Xa ubunzulu budlula uluhlu lokuntywila lomoya, iintlantsi zenziwe lula ngenxa yokwanda koxinzelelo lweoksijini yendawo kwindawo yomoya.Ngoko ke, i-inert okanye i-semi-inert gas kufuneka isetyenziswe kwigumbi legesi.Ngexesha le-welding eyomileyo, i-welders kufuneka inxibe iimpahla ezikhethekileyo zokukhusela umlilo kunye nokushisa okuphezulu.Xa kuthelekiswa ne-welding emanzi kunye nenxalenye eyomileyo, i-welding eyomileyo inokhuseleko olungcono kakhulu, kodwa ukusetyenziswa kwayo kulinganiselwe kakhulu kwaye ukusetyenziswa kwayo akusiyo yonke indawo.

welding owomileyo inxalenye

Indlela eyomileyo yendawo yindlela ye-welding engaphantsi kwamanzi apho i-welder yenza i-welding emanzini kwaye ikhuphe ngokufanelekileyo amanzi malunga nommandla we-welding, kwaye imilinganiselo yayo yokukhusela ifana neyendlela emanzi.

Kuba indlela yokomisa indawo isephantsi kophando, ukusetyenziswa kwayo akukaxhaphakanga.

Ukuwelda okumanzi

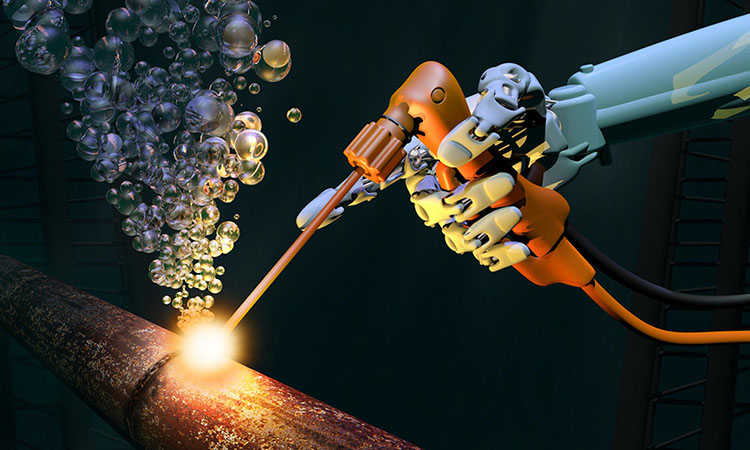

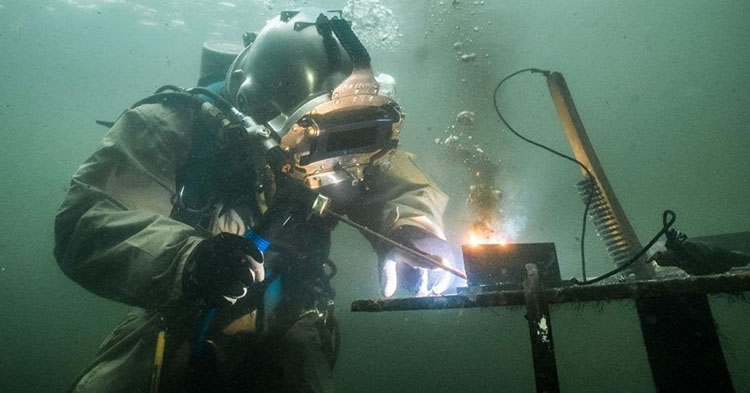

Ukuwelda okumanzi yindlela yokudibanisa ngaphantsi kwamanzi apho i-welder idibanisa ngokuthe ngqo ngaphantsi kwamanzi endaweni yokukhupha amanzi ngokwenziwa kwindawo ejikeleze i-welding.

I-arc evuthayo phantsi kwamanzi ifana ne-arc welding ephantsi kwamanzi, kwaye itshisa kwi-bubbles emoyeni.Xa i-electrode itshisa, i-coating kwi-electrode yenza umkhono ozinzisa amaqamza omoya kwaye ngaloo ndlela uzinzisa i-arc.Ukuze wenze i-electrode itshise ngokuzinzileyo phantsi kwamanzi, kuyimfuneko ukugubungela ubuninzi obuthile bokugquma kwi-electrode core kwaye uyifake ngeparafini okanye ezinye izinto ezingenamanzi ukwenza i-electrode ingangeni manzi.Iibhubhu ziyi-hydrogen, i-oksijini, umphunga wamanzi kunye neebhubhu eziveliswa ngokutshiswa kweengubo ze-electrode;ezinye iioksidi eziveliswa ngumsi omdaka.Ukuze unqobe ubunzima bokutshisa i-arc kunye nokuzinzisa kwe-arc okubangelwa ukupholisa kwamanzi kunye noxinzelelo, i-voltage ye-arc ignition iphezulu kune-atmosfera, kwaye ikhoyo ngoku yi-15% ukuya kwi-20% enkulu kune-welding current emoyeni.

Xa kuthelekiswa ne-welding eyomileyo neyomileyo, i-welding emanzi ngaphantsi kwamanzi inezona zicelo zininzi, kodwa ukhuseleko lolona lubi kakhulu.Ngenxa ye-conductivity yamanzi, ukukhuselwa kwi-shock yombane yenye yezona zinto zixhalabisayo zokhuseleko lwe-welding emanzi.

I-welding emanzi phantsi kwamanzi yenziwa ngokuthe ngqo kumanzi anzulu, oko kukuthi, phantsi komqathango wokuba akukho mqobo womatshini phakathi kwendawo ye-welding kunye namanzi.I-welding ayichaphazeli nje kuphela uxinzelelo lwamanzi ambient, kodwa iphinde ipholiswe ngamandla ngamanzi ajikelezileyo.

Nangona i-welding emanzi ngaphantsi kwamanzi ifanelekile kwaye ibhetyebhetye, kwaye ifuna izixhobo ezilula kunye neemeko, ngenxa yokupholisa okunamandla kwe-arc ye-welding, i-pool etyhidiweyo, i-electrode kunye nentsimbi ye-welding ngamanzi, ukuzinza kwe-arc kutshatyalaliswa, kwaye i-weld shape ihlwempuzekile. .Ummandla oqinileyo wenziwa kwindawo ye-welding echaphazelekayo ukushisa, kwaye isixa esikhulu se-hydrogen singeniswa kwikholamu ye-arc kunye ne-pool etyhidiweyo ngexesha lenkqubo ye-welding, enokuthi ibangele iziphene ezifana nokuqhekeka kwe-welding kunye nama-pores.Ke ngoko, i-welding emanzi ngaphantsi kwamanzi isetyenziswa ngokubanzi kwiindawo ezinamanzi angekho nzulu aneemeko ezintle zolwandle kunye ne-welding yezinto ezingadingi kuxinzelelo oluphezulu.

Imeko ephantsi kwamanzi yenza ukuba inkqubo ye-welding ephantsi kwamanzi ibe nzima kakhulu kunenkqubo ye-welding yomhlaba.Ukongeza kwitekhnoloji ye-welding, ikwabandakanya izinto ezininzi ezifana netekhnoloji yokuntywila.Iimpawu zokuwelda ngaphantsi kwamanzi zezi:

1. Ukubonakala okuphantsi.Ukufunxwa, ukubonakalisa kunye nokuphinda kukhanye ukukhanya ngamanzi kunamandla ngakumbi kunomoya.Ngoko ke, ukukhanya kuba buthathaka ngokukhawuleza xa kusasazeka emanzini.Ukongeza, inani elikhulu lamaqamza kunye nomsi ziveliswa malunga ne-arc ngexesha le-welding, okwenza i-arc engaphantsi kwamanzi ibonakale iphantsi kakhulu.Ukuwelda ngaphantsi kwamanzi kwenziwa kulwandle olunodaka kunye nommandla wolwandle onesanti nodaka, kwaye ukubonakala kwamanzi kubi nakakhulu.

2. I-weld seam iqulethe umxholo ophezulu we-hydrogen, kwaye i-hydrogen lutshaba lwe-welding.Ukuba umxholo we-hydrogen kwi-welding udlula ixabiso elivumelekileyo, kulula ukubangela ukuqhekeka kunye nokukhokelela kumonakalo wesakhiwo.I-arc engaphantsi kwamanzi iya kubangela ukuchithwa kwe-thermal yamanzi ajikelezileyo, okubangelwa ukwanda kwe-hydrogen echithwe kwi-weld.Umgangatho ophantsi we-welded joints of underwater electrode arc welding ayinakuhlukaniswa kumxholo ophezulu we-hydrogen.

3. Isantya sokupholisa siyakhawuleza.Xa udityaniswa ngaphantsi kwamanzi, umoya wokufudumala wamanzi olwandle uphezulu, nto leyo ewuphinda kangangama-20 kunomoya.Ukuba indlela emanzi okanye indlela yendawo isetyenziselwa ukuwelda ngaphantsi kwamanzi, i-workpiece edibeneyo ifakwe ngokuthe ngqo emanzini, kwaye umphumo wokucima amanzi kwi-weld uyabonakala, kwaye kulula ukuvelisa isakhiwo sobunzima obuphezulu.Ngoko ke, umphumo obandayo unokuphetshwa kuphela xa i-welding eyomileyo isetyenziswa.

4. Impembelelo yoxinzelelo, njengoko uxinzelelo lukhula, ikholomu ye-arc iya iba yincinci, ububanzi be-weld bead buba buncinci, ukuphakama kwe-weld seam kuyanda, kwaye ubuninzi be-conductive medium kwandisa, okwandisa ubunzima be-ionization. , i-voltage ye-arc iyanda ngokufanelekileyo, kunye nokuzinza kwe-arc Ukuncitshiswa, ukunyuka kwe-splash kunye nomsi.

5. Ukusebenza okuqhubekayo kunzima ukuqaphela.Ngenxa yempembelelo kunye nokukhawulelana nokusingqongileyo kwamanzi, kwiimeko ezininzi, indlela ye-welding yecandelo elinye kunye nokumisa icandelo elinye kufuneka yamkelwe, okubangela ukuba i-welds ingapheli.

Ukhuseleko lwewelding emanzi ngaphantsi kwamanzi lubi kakhulu kunolo lwasemhlabeni.Awona manyathelo okhuseleko angundoqo ngala:

Umbane othe ngqo kufuneka usetyenziswe kwi-welding engaphantsi kwamanzi, kwaye ukutshintshwa kwangoku akuvumelekanga.I-voltage engekho mthwalo ngokubanzi yi-50-80V.Lawula izixhobo zombane ngokudibana ngokuthe ngqo kunye ne-diving welders kufuneka zisebenzise ii-transformers zodwa kwaye zikhuselwe ngumthwalo ogqithisileyo.Ngaphambi kokuba i-welders diving iqale ukusebenza okanye ngexesha lenkqubo yokutshintsha i-electrode, kufuneka bazise abasebenzi bomhlaba ukuba banqumle isiphaluka.Iintsimbi zokuntywila kufuneka zinxibe iimpahla ezikhethekileyo ezikhuselayo kunye neeglavu ezikhethekileyo.Ngethuba lokutshisa i-arc kunye nokuqhubeka kwe-arc, izandla kufuneka zigwenywe ekuthinteni i-workpieces, iintambo, iintonga ze-welding, njl.Ngethuba lemisebenzi ye-welding engaphantsi kwamanzi, ukukhuselwa kococeko lwabasebenzi, ngokukodwa ukukhuselwa kwedolophu kunye nokukhuselwa kokutshisa kufuneka kubonelelwe.Jonga rhoqo ukusebenza kwe-insulation kunye nokusebenza kokungena kwamanzi kwezixhobo ze-welding ezingaphantsi kwamanzi, i-welding tongs, iintambo, njl.

Ixesha lokuposa: Jul-12-2023