Ngexesha le-welding ye-fusion, phantsi kwesenzo somthombo wobushushu we-welding, inxalenye yentsimbi engamanzi kunye nemilo ethile yejometri eyenziwe kwi-weldment yintsimbi ye-electrode etyhidiweyo kunye nenxalenye etyhidiweyo yesiseko sesinyithi yichibi elityhidiweyo.Emva kokupholisa, kuba yi-weld, ngoko ubushushu be-pool etyhidiweyo buchaphazela ngokuthe ngqo umgangatho we-welding.

Ukuba iqondo lobushushu lechibi elinyibilikisiweyo liphezulu, ichibi elityhidiweyo likhulu, kwaye isinyithi esityhidiweyo sinobumanzi obuhle, indawo yokudibanisa kulula ukuyidibanisa;kodwa xa iqondo lobushushu liphezulu kakhulu, kulula ukuthontsiza intsimbi enyibilikisiweyo, kwaye icala elingasemva le-welding enecala elinye kunye nokwakheka kwamacala amabini kulula ukutshisa, ukwenza amaqhuma weld, kunye nokumila.Kunzima ukulawula, kwaye iplastiki yokudibanisa iyancitshiswa, kwaye ukudibanisa kulula ukuqhekeza;xa iqondo lobushushu lechibi elinyibilikisiweyo lisezantsi, idama elityhidiweyo lincinci, intsimbi etyhidiweyo iba mnyama, kwaye ulwelo lubi.Kulula ukuvelisa iziphene ezifana nokungena okungaphelelanga, ukungabikho kokudibanisa, kunye nokufakwa kwe-slag.

Ngoko ke, ukulawula ngokufanelekileyo ubushushu be-pool etyhidiweyo kubaluleke kakhulu ukuqinisekisa umphumo we-welding kunye nomgangatho wemveliso egqityiweyo.

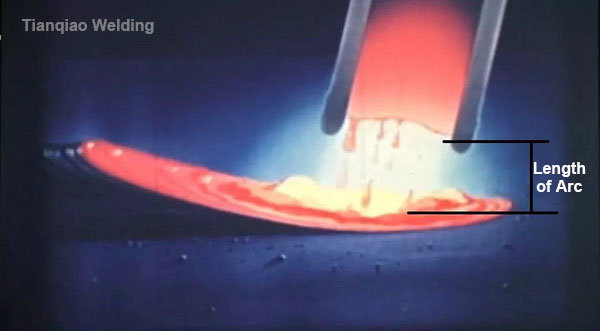

Umzobo we-1 Tianqiao welding

Ubushushu bechibi elityhidiweyo lihambelana ngokusondeleyo kwi-welding current, ububanzi be-electrode, indlela yokuthutha, i-angle ye-electrode, kunye nexesha lokutshisa i-arc.La manyathelo alandelayo athatyathwa ukulawula ubushushu bedama elinyibilikisiweyo ngokwemiba efanelekileyo.

1. I-Welding yangoku kunye nedayimitha ye-electrode

Le miba mibini yimiba ebalulekileyo ye-welding, kwaye ezi zimbini zinesibopho esingenakuhlukaniswa.Ngexesha lokudibanisa i-welding, i-current flowing back through weldment ibizwa ngokuba yi-welding current.I-diameter ye-electrode ibhekisela kubungakanani becandelo lomnqamlezo wentonga yentsimbi yokuzalisa.Ngamagama alula, ingaba intonga ye-welding inokuncibilika ngokufanelekileyo igqitywe ngokugqithiswa kwangoku.

Ukuba i-current incinci kakhulu, kunzima ukuqala i-arc, i-electrode kulula ukunamathela kwi-weldment, izikali zeentlanzi zinzima, kwaye amacala amabini awaxutywanga;ukuba i-current ikhulu kakhulu, i-splash kunye nomsi ngexesha le-welding iya kuba nkulu, i-electrode iya kuba bomvu, kwaye umphezulu we-pool etyhidiweyo uya kuqaqamba kakhulu.Kulula ukutshisa kunye nokunciphisa;xa umsinga ufanelekile, kulula ukuvutha kwaye i-arc izinzile, i-splash incinci, isandi esifanayo esiqhekezayo sinokuvakala, amacala amabini e-welding seam aguquguqukayo atshintshela kwizinto ezisisiseko, izikali zeentlanzi eziphezulu kakhulu. obhityileyo, kunye slag welding kulula Knock ngaphandle.Ngokuphathelele ukusetyenziswa kwayo, kukho ubudlelwane obunzima.

1.1 Khetha i-welding current kunye ne-diameter ye-electrode ngokwendawo yendawo ye-weld

Kwizikhundla ezithe nkqo, ezithe tye kunye nezithe tye, i-current incinci ngokuhambelanayo kuneye-flat welding, kwaye yangoku kufuneka ibe malunga ne-10% encinci kuneyo ye-flat welding.

Ngokufanayo, kwiindawo ezithe nkqo, ezithe tye, kunye nezithe tye, ububanzi be-electrode buhlala buncinci kunelo lwe-flat welding.Ngokomzekelo, kwi-welding flat ye-flat plate enkulu kune-12mm, i-electrode ye-5.0mm isoloko isetyenziswa., Kwaye akukho phantse i-electrode enobubanzi be-5.0mm kwiindawo ezithe nkqo, ezithe tye nezithe tye.

1.2 I-welding current kunye ne-electrode diameter ikhethwe ngokwezinga le-welding ye-weld.

Umzekelo, kwi-12mm ipleyiti ecwebileyo ye-butt joints, 3.2mmIi-electrodes zeTianqiaozisetyenziswa ngokubanzi kumaleko asezantsi we welding flat, kwaye ngoku welding yi 90-110A, kunye 4.0mm.Ii-electrodes zeTianqiaoingasetyenziselwa ukuzaliswa kunye nokugubungela umaleko, kunye ne-welding current yi-160-175A.

Ngoko ke, ukhetho olufanelekileyo lwe-welding current kunye nobubanzi be-electrode bungakwazi ukulawula ngokulula ukushisa kwechibi elityhidiweyo, elisisiseko sokwakheka kakuhle kwe-weld.Ukuba i-welding current incinci kakhulu, ukushisa kwe-weld pool kuphantsi kakhulu, kubangela ukuba i-arc ingazinzi, kwaye i-workpiece ayinakuxutywa.Ukuba umsinga wokuwelda uphezulu kakhulu kwaye nobushushu bedama elinyibilikisiweyo buphezulu kakhulu, oko kuya kubangela ukutshiza okumandla kunye nokuhamba kwesinyithi esinyibilikisiweyo, kwaye kude kutshise kwisixhobo sokusebenza ukwenza i-welding bead.

Ubudlelwane phakathi kwe-welding current kunye nobubanzi be-electrode zidweliswe ngezantsi.Unokwenza ukhetho olufanelekileyo ngokusekelwe kumava akho okanye imikhwa.Awudingi ukumisela iiparamitha ezifanayo nabanye, ukuba nje uziva ukuba kufanelekile kwaye uqinisekise ukwakheka kwe-weld elungileyo.

2. Ukuthuthwa kwentonga ye-welding

Iintonga ye-weldingityiswa kwicala ledama elityhidiweyo ecaleni kweasi.Emva kokuba intonga ye-welding iyancibilika, ubude be-arc bunokuqhubeka nokugcinwa.Ngoko ke, isantya sentonga ye-welding kwicala le-pool etyhidiweyo kufuneka ilingane nesantya sokunyibilika kwentonga ye-welding.

Ukuba isantya sokutya se-electrode singaphantsi kwesantya sokunyibilika kwe-electrode, ubude be-arc buya kunyuka ngokuthe ngcembe, okubangelwa ukuphazamiseka kwe-arc;ukuba isantya sokutya se-electrode sikhawuleza kakhulu, ubude be-arc buya kufinyezwa ngokukhawuleza, kwaye isiphelo se-electrode siya kuba sifutshane-sijikelezwe ngokuqhagamshelana ne-weldment.Ukucima i-arc.

Umzobo we-2 welding ye-Tianqiao

3. I-angle yokuhanjiswa kunye nesikhundla sokutya

Ngexesha le-welding, i-angle ye-electrode kufuneka itshintshe kunye ne-welding position, kwaye ihlale igcina ubushushu be-pool etyhidiweyo kumacala omabini omgca onqabileyo ofanelekileyo.Ukuba iqondo lokushisa liphezulu kakhulu, liya kubangela ukutshisa, kwaye ukuba liphantsi kakhulu, liya kubangela ukwenzeka kokungena ngokwaneleyo kunye nokudibanisa.Xa i-angle phakathi kwe-electrode kunye nolwalathiso lwe-welding yi-90 degrees, i-arc igxininiswe kwaye iqondo lokushisa le-pool etyhidiweyo liphezulu;

Ukuba i-engile iba yincinci, i-arc iya kusasazwa kwaye ubushushu bedama elinyibilikisiweyo buya kuba sezantsi.Umzekelo, ukuba umaleko osezantsi we-12mm flat welding itywina, ukuba i-engile ye-welding intonga yi-50-70 degrees, iqondo lobushushu lechibi elityhidiweyo liya kuthotywa ngeli xesha, kwaye umcimbi we-welding bead okanye ukunyuka kwicala elingasemva. iyaphetshwa.Omnye umzekelo, emva kokutshintsha intonga ye-welding ezantsi kwe-12mm ipleyiti yetywina ye-welding ethe nkqo, sisebenzisa i-90-95 degree welding engile xa sithutha intonga ye-welding, ukwenzela ukuba ubushushu bechibi elityhidiweyo bunokunyusa ngokukhawuleza, umngxuma otyhidiweyo unokuvulwa ngokutyibilikayo, kwaye umphezulu ongasemva wenziwa mcaba, onokulawulwa ngokufanelekileyo.Isenzeko sokuba inqaku elidibeneyo li-concave.

Ukuba indawo yokutya ye-electrode ayanelanga, iya kubangela ukungena ngokwaneleyo okanye i-groove clamping.Ngenxa yokuba i-arc ihlakazekile ngeli xesha, ukushisa okunyibilikayo komphetho onqabileyo wezinto ezisisiseko akwanele, okubangelwa ukuchithwa kwezinto ezisisiseko phantsi;ukuba ufuna ukunyibilika ngokupheleleyo isinyithi, kufuneka ukwandise ixesha lokunyibilika.I-Welding, i-multi-layer superposition ye-pool etyhidiweyo iya kuvelisa into yokubandakanywa kwe-slag.

Indlela echanekileyo kukwandisa intonga ye-welding kwi-groove edge edge kwi-engile ye-75 degrees, ukulungelelanisa isiseko se-groove ukuze sinyibilike kwaye sijingi macala omabini, isenzo ngasinye sithatha malunga ne-1 yesibini, ukuza kuthi ga ngoku i-pool yokuqala etyhidiweyo yenziwe, kwaye emva koko ingene elandelayo Ukubunjwa kwedama elityhidiweyo.Ngeli xesha, ixesha lokunyibilika kwechibi ngalinye elityhidiweyo lifutshane kwaye ubunzima bulula, kwaye akufanelekile ukubangela ukuwa, kwaye i-welding bump ayiyi kubumba.Umjelo ongenzulu nawo unceda ukuwelda komphezulu wokugquma.

Idama elinyibilikisiweyo lokugqibela ligubungela i-2/3 yangaphambili.Idama ngalinye elinyibilikisiweyo lincinci, kwaye le yokugqibela idlala isiphumo sokunyibilika kwe-post-heat kwenye yangaphambili, iqinisekisa ukuba irhasi ekwidama elinyibilikisiweyo inexesha elaneleyo lokuphuphuma kwaye ithintele ukuba ingaveli.Stomata.

Umzobo we-3 welding ye-Tianqiao

4. Ixesha lokutshisa i-arc

Kwinkqubo yokufundisa i-welding ethe tye kunye nethe nkqo ye-welding ye-57 × 3.5 imibhobho, indlela yokuqhawula i-arc isetyenziselwa i-welding.Xa uqala i-welding, ukushisa kwesiseko sentsimbi kuphantsi.Ukuba intonga ye-welding ayifakwanga kumda we-groove, intsimbi etyhidiweyo iya kuncipha ngokukhawuleza kwaye ivelise i-undercuts.Ukubunjwa kwe-weld kuya kuba phezulu kwaye kuncinci, okungayi kufezekisa umphumo wokugqithisa ngokugqithiseleyo, kwaye kulula Isiphumo esiphumelayo asixutywanga.

Ukuhlalutya ukusuka kwimilo yedama elityhidiweyo, ukuba likwimo yedropha ewayo, imilo edibeneyo ayilungile, kwaye i-welding bead ingenzeka.Ke ngoko, indawo ye-welding kufuneka itshiswe ngokupheleleyo ukusuka kwi-welding ephezulu.I-angle phakathi kwe-electrode kunye nombhobho ngama-75 degrees.Emva kokuba i-arc igxothwe, i-arc yoluliwe ukwenzela ukutshisa.Emva kokuwa kwentsimbi yokuqala etyhidiweyo kwintloko ye-electrode, i-electrode ithunyelwa.

Ubushushu bechibi elinyibilikisiweyo ngeli xesha kufuneka liqinisekise ukuba ubungakanani bechibi elinyibilikisiweyo bububanzi begroove kunye ne-1 mm, ukuze izinto ezisisiseko zinyibilike ngokupheleleyo kwi-droplet ukwenza i-weld.

Kwintsebenzo ye-welding yangempela, kuyimfuneko ukufunda ukujonga utshintsho kwiqondo lokushisa kwi-pool etyhidiweyo kunye nokuqonda indlela yokulawula ngokufanelekileyo ubushushu be-pool etyhidiweyo, eyona siseko sokufunda iteknoloji ye-welding.Kuyimfuneko ukuba ukwazi ukugweba i-angle ye-welding intonga, indawo yokutya kunye nexesha lokunyibilika ngokwe-pool etyhidiweyo yecandelo ngalinye, ngokukhawuleza ubambe iteknoloji yokusebenza yamacandelo amaninzi abalulekileyo, kwaye emva kwexesha loqeqesho lokwenyani, inqanaba lobugcisa liya kuphucula. ngokukhawuleza, kunye nezinga lokwenzeka kweziphene ezahlukeneyo welding Isezantsi kakhulu, ukuphucula umthamo woxinzelelo kwi-welding yolwakhiwo oluntsonkothileyo, olulungele ukuphuculwa kobuchwephesha bokuwelda kwixa elizayo.

Ixesha lokuposa: Jul-15-2021