I-electrode ye-welding yintonga yensimbi enyibilikayo kwaye izaliswe kwi-joint of the welding work-piece ngexesha lokutshisa igesi okanye i-welding yombane.Izinto eziphathekayo ze-electrode zidla ngokufana nempahla yomsebenzi.

Apha siza kuqonda ukuba i-electrode ye-welding yenziwe njani:

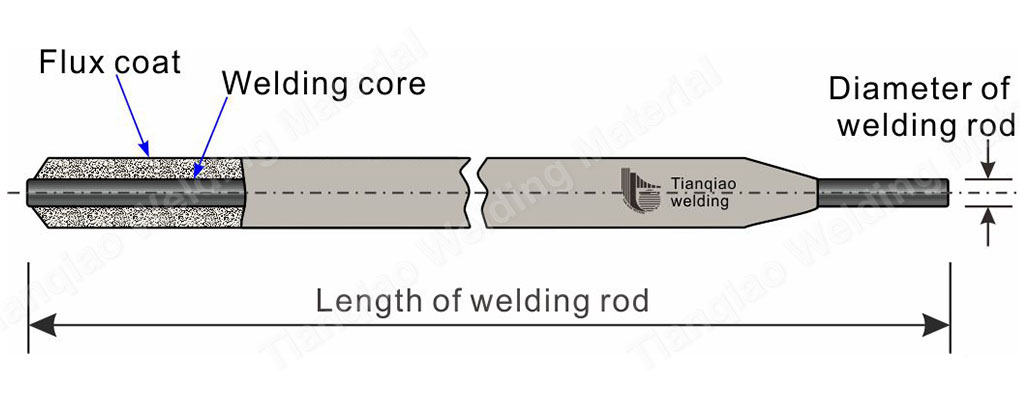

Umzobo 1 Ulwakhiwo lwe-electrode ye-welding ye-Tianqiao

I-electrode ye-welding yi-electrode enyibilikayo ehlanganiswe ngengubo ye-arc welding yentonga ye-welding.Iqulethwe ngengubo kunye ne-welding core.

Undoqo wesinyithi ogqunywe ngokugquma kwintonga ye-welding ibizwa ngokuba yiwelding core.I-welding core ngokubanzi intambo yensimbi enobude obuthile kunye nobubanzi.

Umzobo we-2 Core we-Tianqiao welding electrode

Imisebenzi emibini yondoqo

1. Ukuqhuba i-welding current kwaye uvelise i-arc ukuguqula amandla ombane kubushushu.

2. I-welding core ngokwayo iyanyibilika njengentsimbi yokuzalisa kunye ne-fuses kunye nesiseko sesinyithi solwelo ukwenza i-weld.Xa udibanisa nge-electrode, intsimbi engundoqo ithatha inxalenye yentsimbi ye-weld yonke.Ngoko ke, ukubunjwa kweekhemikhali ze-weld core kuchaphazela ngokuthe ngqo umgangatho we-weld.Ngoko ke, ucingo lwensimbi olusetyenziswe njengengundoqo ye-electrode inophawu kunye nokubunjwa okuchazwe ngokwahlukileyo.

Electrode ukutyabekaibhekisa kumaleko okwambathisa asetyenziswa kumphezulu we-welding core.I-coating ichithwa kwaye inyibilika kwinkqubo ye-welding ukwenza igesi kunye ne-slag, edlala indima ekukhuselweni komatshini, unyango lwe-metallurgical, kunye nokuphuculwa kwenkqubo yokusebenza.

Umzobo we-3 Ukwaleka kwe-electrode ye-welding ye-Tianqiao

Ukubunjwa kokugquma kubandakanya: iiminerali (ezifana nebhastile, i-fluorspar, njl.), ii-ferroalloys kunye ne-metal powders (ezifana ne-ferromanganese, i-ferro-titanium, njl.), izinto eziphilayo (ezifana nomgubo womthi, i-cellulose, njl.), iimveliso zeekhemikhali (ezifana ne-titanium dioxide, iglasi yamanzi, njl.).Ukugquma kwe-Electrode yinto ebalulekileyo ekunqumeni umgangatho wee-welds.

Imisebenzi ephambili yokwaleka kwinkqubo ye-welding

1. Phucula uzinzo lokutsha kwe-arc:

I-electrode engabonakaliyo ayilula ukutshisa i-arc.Nokuba ithe yatshiswa, ayinakutsha ngokuzinzileyo.

2. Khusela i-weld pool:

Ngethuba lenkqubo ye-welding, i-oksijeni, i-nitrogen kunye nomphunga wamanzi emoyeni ingena kwi-weld seam, eya kuba nefuthe elibi kwi-weld seam.Akukona nje ukubunjwa kwee-pores, kodwa kwakhona ukunciphisa iimpawu ze-mechanical weld, kwaye zibangele nokuqhekeka.Emva kokuba i-electrode coating iyancibilika, inani elikhulu legesi lenziwa ligubungele i-arc kunye ne-pool etyhidiweyo, eya kunciphisa intsebenziswano phakathi kwesinyithi esityhidiweyo kunye nomoya.Xa i-weld ipholile, i-coating encibilikisiweyo yenza uluhlu lwe-slag, olugubungela umphezulu we-weld, lukhusela i-weld metal kwaye luyipholise ngokukhawuleza, lunciphisa amathuba okuba ne-porosity.

Okwesithathu, ukuqinisekisa ukuba i-weld i-deoxidized kwaye i-desulfurized kunye nokungcola kwe-phosphorus

Nangona ukhuseleko lwenziwa ngexesha lenkqubo ye-welding, kusengenakuphepheka ukuba i-oksijini encinci iya kungena echibini elityhidiweyo ukuze i-oxidize isinyithi kunye nezinto ze-alloy, ukutshisa izinto ze-alloy, kunye nokunciphisa umgangatho we-weld.Ngoko ke, kuyimfuneko ukongeza i-agent yokunciphisa (njenge-manganese, i-silicon, i-titanium, i-aluminium, njl.) kwi-electrode coating ukunciphisa i-oxides engene kwi-pool etyhidiweyo.

4. Yongeza iziqalelo zengxubevange ye weld:

Ngenxa yefuthe eliphezulu lokushisa kwe-arc, i-alloying elements ye-weld metal iya kuba ngumphunga kwaye itshiswe, eya kunciphisa iimpawu zomatshini we-weld.Ngoko ke, kuyimfuneko ukongeza izinto ezifanelekileyo zokudibanisa kwi-weld ngokusebenzisa i-coating ukuhlawulela ilahleko etshiswayo yezinto ze-alloy kunye nokuqinisekisa okanye ukuphucula iimpawu zomatshini we-weld.Ukudibanisa ezinye iintsimbi ze-alloy, kuyafuneka ukuba ungene kwi-alloy kwi-weld ngokusebenzisa i-coating, ukuze isinyithi se-weld sibe kufuphi nokwakhiwa kwesinyithi sesiseko sesinyithi, kunye neempawu zoomatshini zinokubamba okanye zidlule. isiseko sesinyithi.

5. Ukuphucula imveliso ye-welding kunye nokunciphisa i-spatter:

I-electrode coating inefuthe lokunyusa i-droplet kunye nokunciphisa i-spatter.Indawo yokunyibilika yengubo ye-electrode ingaphantsi kancinci kunendawo ye-welding ye-core.Nangona kunjalo, ngenxa yokuba i-welding core isembindini we-arc kwaye iqondo lokushisa liphezulu kakhulu, i-welding core iyanyibilika kuqala, kwaye i-coating iyanyibilika kancinane kamva.Ngelo xesha, ekubeni ilahleko yesinyithi ebangelwa yi-spatter iyancitshiswa, i-coefficient yokubeka i-deposition iyanda, kwaye imveliso ye-welding nayo iphuculwe.

Ixesha lokuposa: Jun-01-2021