Inkqubo ye-arc welding ye-arc ephantsi kwamanzi iyona khetho ifanelekileyo kwiinkalo ezibalulekileyo zesicelo semibhobho, iinqanawa zoxinzelelo kunye namatanki, ukuveliswa komkhondo kunye nokwakhiwa okukhulu.Ineyona fom ilula yocingo olunye, isakhiwo socingo oluphindiweyo, uthotho lwesakhiwo socingo oluphindwe kabini kunye nolwakhiwo lweengcingo ezininzi.

Inkqubo ye-arc welding ephantsi kwamanzi inokunceda abasebenzisi kwizicelo ezininzi ze-welding, ukusuka kwimveliso eyandisiweyo ukuya kwiimeko eziphuculweyo zokusebenza ukuya kumgangatho ongaguqukiyo kunye nokunye.Izityalo ezenziwe ngesinyithi ezicinga ukwenza utshintsho kwinkqubo ye-welding ye-arc ephantsi kwamanzi kufuneka icinge ngeenzuzo ezininzi ezinokufumaneka kule nkqubo.

Ulwazi olusisiseko lwe-arc welding ephantsi kwamanzi

Inkqubo ye-arc welding ephantsi kwamanzi ifanelekile kwiimfuno ezinzima zesicelo semizi-mveliso yombhobho, iinqanawa zoxinzelelo kunye namatanki, ukwakhiwa kwe-locomotive, ukwakhiwa okunzima / ukumba.Ilungele amashishini afuna imveliso ephezulu, ngakumbi leyo ibandakanya ukuwelda kwemathiriyeli engqindilili kakhulu, enokuzuza kakhulu kwinkqubo ye-arc yokuntywila.

Izinga layo eliphezulu lokubeka kunye nesantya sokuhamba linokuba nefuthe elibalulekileyo kwimveliso yabasebenzi, ukusebenza kakuhle kunye neendleko zokuvelisa, enye yeenzuzo eziphambili zenkqubo ye-arc welding ephantsi kwamanzi.

Izibonelelo ezongezelelweyo zibandakanya: ii-welds ezinokwakheka kweekhemikhali ezigqwesileyo kunye neepropathi zoomatshini, ukubonakala kwe-arc encinci kunye ne-welding fume ephantsi, ukuphuculwa kwemeko yendawo yomsebenzi, kunye nokuma okuhle kwe-weld kunye nomgca weenzwane.

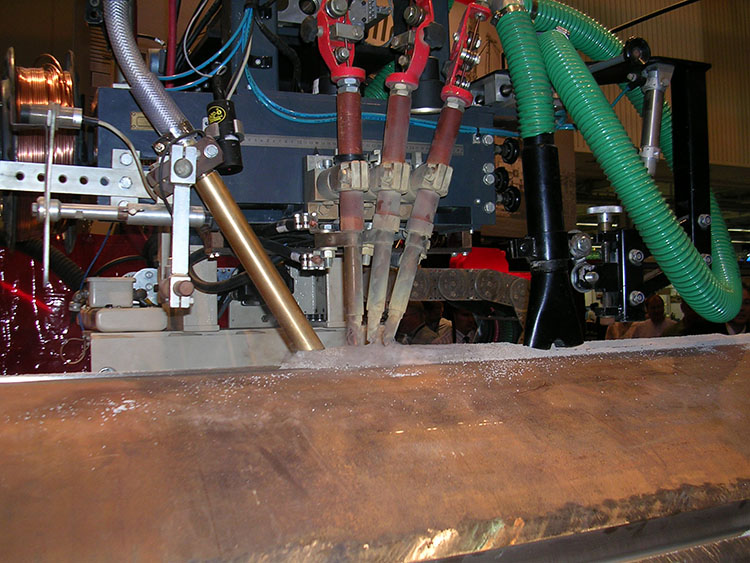

I-arc welding ephantsi kwamanzi yindlela yokutya yocingo esebenzisa i-granular flux ukwahlula i-arc emoyeni.Njengoko igama libonisa, i-arc ingcwatywe kwi-flux, oku kuthetha ukuba xa iiparitha zisetwa, i-arc ayibonakali kunye nokuhamba koluhlu olulandelayo lwe-flux.

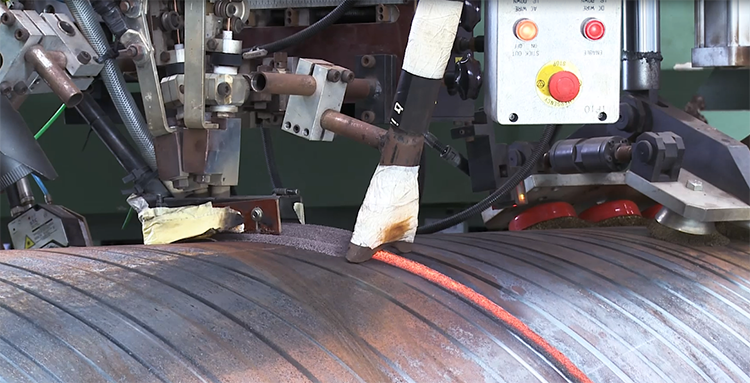

Ucingo lutyiswa rhoqo ngetotshi ehamba ecaleni kweweld.Ukufudumeza kwe-Arc kunyibilikisa icandelo locingo, inxalenye ye-flux kunye nesiseko sezinto zokwenza i-pool etyhidiweyo, edibanisayo ukuze yenze i-weld ehlanganiswe ngoluhlu lwe-welding slag.

Uluhlu lwezinto ezityebileyo ze-welding yi-1/16 "-3/4", enokuthi ibe yi-100% yokungena kwi-welding ngokusebenzisa i-welding enye yokudlula, ukuba ubukhulu bodonga abuphelelanga, bunokuba yi-welding ye-multi-pass, kwaye iqhutywe ngokufanelekileyo. ukhetho lonyango lwangaphambili lwe-weld, kwaye ukhethe udibaniso olufanelekileyo lwe-wire flux.

I-Flux kunye nokukhethwa kweengcingo

Ukukhetha i-flux efanelekileyo kunye nocingo lwenkqubo ethile ye-arc welding ye-arc ibaluleke kakhulu ekufezekiseni iziphumo ezilungileyo ngaloo nkqubo.Nangona inkqubo yokudibanisa i-arc ephantsi kwamanzi iyodwa isebenzayo, imveliso kunye nokusebenza kakuhle kunokunyuswa ngokusekwe kucingo kunye ne-flux esetyenzisiweyo.

I-flux ayikhuseli kuphela i-weld pool, kodwa igalelo ekuphuculeni iimpawu zomatshini kunye nemveliso ye-weld.Ukuqulunqwa kwe-flux yimpembelelo enkulu kule miba, echaphazela amandla okuphatha ngoku kunye nokukhululwa kwe-slag.Umthamo wangoku wokuthwala uthetha ukuba obona buchule buphezulu bokubekwa kunye neprofayile yeweld esemgangathweni inokufumaneka.

Ukukhutshwa kwe-slag ye-flux ethile kuchaphazela ukukhethwa kwe-flux kuba ezinye ii-fluxes zifaneleka ngakumbi kuyilo oluthile lwe-welding kunabanye.

Izinketho zokukhetha i-Flux kwi-arc welding ephantsi kwamanzi ibandakanya iintlobo ezisebenzayo kunye nezingathathi hlangothi ze-welding.Umahluko osisiseko kukuba i-flux esebenzayo itshintsha i-chemistry ye-weld, ngelixa i-neutral flux ayifuni.

I-flux esebenzayo ibonakala ngokubandakanywa kwe-silicon kunye ne-manganese.Ezi zinto zinceda ukugcina amandla e-weld tensile ekufakweni kobushushu obuphezulu, nceda i-weld ihlale igudileyo kwizantya eziphezulu zokuhamba kunye nokubonelela ngokukhululwa kwe-slag elungileyo.

Ngokubanzi, i-flux esebenzayo inokunceda ukunciphisa umngcipheko womgangatho ophantsi we-welding, kunye nokucoca emva kwe-weld kunye nokusebenza kwakhona.

Gcina ukhumbula, nangona kunjalo, ukuba i-flux esebenzayo ihlala ilungile kwi-welding enye okanye kabini.Ii-fluxes ezingathathi hlangothi zingcono kwii-welds ezinkulu ze-multi-pass kuba zinceda ukuphepha ukwenza i-brittle, i-weld-sensitive welds.

Kukho iinketho ezininzi zeengcingo ze-arc welding ephantsi kwamanzi, nganye inenzuzo kunye nokungalunganga.Ezinye iingcingo zenzelwe i-welding kumagalelo aphezulu obushushu, ngelixa ezinye ziyilelwe ngokukodwa ukuba zibe ne-alloys ezinceda i-flux icoce i-weld.

Qaphela ukuba iimpawu zeekhemikhali zocingo kunye nokusebenzisana kwegalelo lobushushu kunokuchaphazela iimpawu zemishini ye-weld.Imveliso ingaphuculwa kakhulu ngokuzalisa ukhetho lwesinyithi.

Ngokomzekelo, ukusebenzisa i-metal-cored wire kunye nenkqubo ye-arc welding ephantsi kwamanzi kunokunyusa ukusebenza kwe-deposition nge-15 ukuya kwi-30 yeepesenti xa kuthelekiswa nokusebenzisa ucingo oluqinileyo, ngelixa libonelela ngeprofayili yokungena ebanzi, enzulu.

Ngenxa yesantya esiphezulu sokuhamba, ucingo lwentsimbi lukwanciphisa igalelo lobushushu ukunciphisa umngcipheko wokuphazamiseka kwe-welding kunye nokutshiswa.Xa ungathandabuzi, jongana nomenzi wentsimbi yokuzalisa ukuze ubone ukuba yeyiphi imidibaniso yocingo kunye neyokuqukuqela eyona ilungileyo kwisicelo esithile.

Ixesha lokuposa: Jun-27-2023