Niniwelding steel stainless, ukusebenza kwe-electrode kufuneka kuhambelane nenjongo yensimbi engenasici.I-electrode yensimbi engenasici kufuneka ikhethwe ngokwesiseko setsimbi kunye neemeko zokusebenza (kubandakanya ukushisa okusebenzayo, i-medium medium, njl.).

Iindidi ezine zensimbi engenasici kunye nezinto ezixutywayo zisetyenziswa

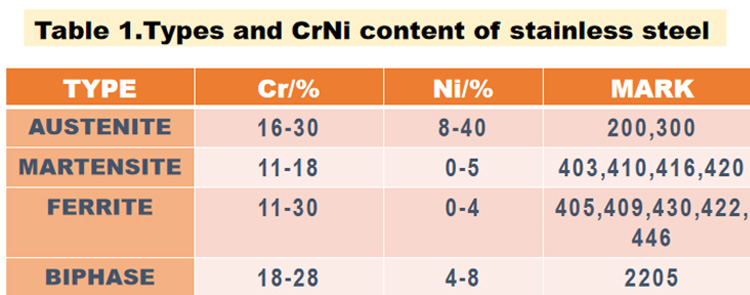

Insimbi engenasici inokwahlulwa ibe ziindidi ezine: i-Austenitic, i-martensitic, i-ferritic kunye ne-biphase insimbi engenasici, njengoko kubonisiwe kwiThebhile 1.

Oku kusekelwe kwisakhiwo se-metallographic yensimbi engenasici kwiqondo lokushisa.Xa intsimbi ethambileyo ifudunyezwa1550° F, ulwakhiwo lutshintsha ukusuka kwinqanaba lobushushu begumbi ukuya kwinqanaba le-austenitic.Xa ipholile, isakhiwo sentsimbi esithambileyo siguqulwa sibuyele kwi-ferrite.Izakhiwo ze-Austenitic ezikhoyo kubushushu obuphezulu azinamagnetic kwaye zinamandla amancinci kunye nokuqina kunezakhiwo ze-ferrite zobushushu begumbi.

Indlela yokukhetha izinto ezifanelekileyo ze-welding steel stainless?

Ukuba izinto ezisisiseko ziyafana, umthetho wokuqala "uhambelana nesiseko".Umzekelo, khetha izinto ze-welding310 or 316yenziwe ngentsimbi eshayinayo.

Ukudibanisa izinto ezingafaniyo, imilinganiselo yokukhetha isiseko esinomxholo ophezulu we-alloying iyalandelwa.Ngokomzekelo, ukuba i-304 okanye i-316 insimbi engenasici i-welded, khetha uhlobo316.

Kodwa kukho kwakhona abaninzi abawulandeli umgaqo "ohambelanayo wesiseko" weemeko ezikhethekileyo, ngoko kuyimfuneko "ukubonisana netafile yokukhetha izinto ze-welding".Umzekelo, chwetheza304insimbi engenasici yeyona ixhaphakileyo isiseko sentsimbi, kodwa akukho Uhlobo304i-electrode.

Ukuba i-welding material ihambelana nesiseko sezinto, indlela yokukhetha i-welding material to weld304yenziwe ngentsimbi eshayinayo?

Xa welding304insimbi engenasici, sebenzisa uhlobo308izinto welding, kuba izinto ezongezelelweyo kwi308insimbi engenasici inokuzinzisa ngcono indawo ye-weld.

308L ikwayindlela eyamkelekileyo.U-L uthetha umxholo wekhabhoni ephantsi,3I-XXL yentsimbi ye-carbon content ≤0.03%, kunye nomgangatho3XXintsimbi engatyiwa ingaqulatha ukuya kuthi ga0.08%umxholo wekhabhoni.

Ngenxa yokuba ukuwelda okumilise okwe-L kuluhlobo olufanayo lolwahlulo njenge-welding engekho-L, abavelisi kufuneka banike ingqwalasela ekhethekileyo ekusebenziseni i-welding efana ne-L kuba umxholo wekhabhoni ephantsi unciphisa ukutyekela kwi-corrosion ye-intergranular (jonga uMfanekiso 1).

Indlela yokudibanisa insimbi engenasici kunye ne-carbon steel?

Ukunciphisa iindleko, ezinye izakhiwo ze-weld umaleko wokumelana nokubola kumphezulu we-carbon steel.Xa udibanisa izinto ezisisiseko ngaphandle kwezinto ezixutywayo kunye nesiseko sezinto eziphathekayo, sebenzisa i-welding material kunye ne-alloying content ephezulu ukulinganisa izinga lokuhlanjululwa kwi-weld.

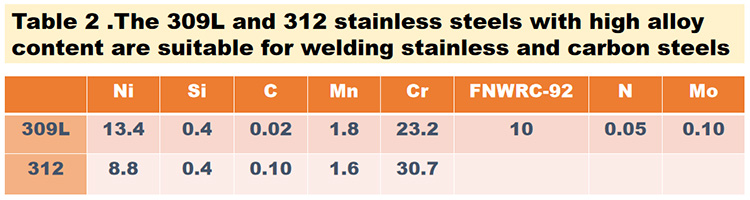

Xa welding carbon steel nge304 or 316insimbi engenasici kunye nenye intsimbi engafaniyo (jonga iTheyibhile 2),309L izinto zokuweldakufuneka ithathelwe ingqalelo kwiimeko ezininzi.Ukuba ufuna ukufumana umxholo ophezulu we-Cr, khetha uhlobo312.

Yintoni umsebenzi ofanelekileyo wokucoca kwangaphambili?

Xa u-welding kunye nezinye izinto, susa kuqala ioli, amanqaku kunye nothuli nge-solvent engena-chlorine.Ukongeza, into yokuqala ekufuneka uyithathele ingqalelo xa i-welding steel stainless steel kukuphepha ukungcoliswa yi-carbon steel kwaye ichaphazele ukuqina kwe-corrosion.Ezinye iinkampani zigcina insimbi engenasici kunye ne-carbon steel ngokwahlukileyo ukuze ziphephe ukungcoliseka.Sebenzisa amavili akhethekileyo okusila kunye neebrashi zensimbi engenasici xa ucoca indawo ejikeleze i-groove.Ngamanye amaxesha umdibaniso ufuna ukucocwa okwesibini.Ngenxa yokuba ukusebenza kwembuyekezo ye-electrode ye-stainless steel welding inzima ngakumbi kune-carbon steel welding, ukucoca ngokubambisana kubaluleke kakhulu.

Ixesha lokuposa: May-09-2023