Ngophuhliso olukhawulezayo lweshishini lepetrochemical, izixhobo zensimbi ezingenasici zisetyenziswe ngokubanzi, nto leyo ethe yabeka phambili iimfuno eziphezulu zokudityaniswa kwemibhobho kunye neepleyiti.Indlela yangaphambili yentsimbi ye-arc welding primer iye yapheliswa ngokuthe ngcembe, kwaye i-argon arc welding isetyenziselwa i-primer welding.

I-Argon arc welding primer icocekile kwaye ikhawuleza kune-arc welding primer.Kwangaxeshanye, kukho iingxaki ezithile.

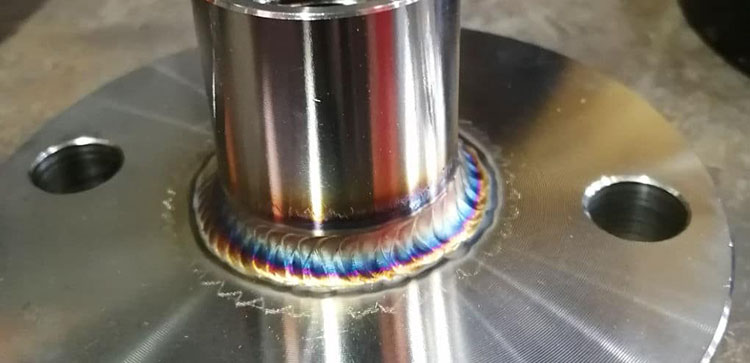

Ngethuba lenkqubo ye-welding, ekubeni umva wesiseko sentsimbi ye-argon ye-arc welding i-oxidized ngokulula kwaye ibangela iziphene, amanyathelo okukhusela umva kufuneka athathwe ukuze kuqinisekiswe iipropati ze-mechanical kunye nokumelana nokubola kwe-weld.Ngoko ke, ukukhuselwa okusebenzayo kufuneka kuthathwe xa welding steel stainless.

Namhlanje sazisa iindlela ezininzi ezisetyenziswa ngokuqhelekileyo intsimbi estainless welding ukhuseleko ngasemva:

01

Indlela yoKhuseleko lweArgon ngasemva

Iigesi zokukhusela ezisetyenziswa ngokuqhelekileyo zingahlulwa zibe yi-argon elula yokukhusela igesi kunye nokukhuselwa kwegesi edibeneyo.Umlinganiselo othile we-argon-nitrogen yegesi exubeneyo inceda ngakumbi kwi-austenitic stainless steel welding.Ezinye iigesi ezingenamsebenzi azisetyenziswanga ngenxa yeendleko zazo eziphezulu.

Indlela yokuzaliswa kweArgon yindlela yokukhusela umva ngokwesiko, eneempawu zokukhusela umva ongcono, kulula ukuyiqonda, ukucoceka okuphezulu, kunye nezinga eliphezulu lokupasa.Ukwahlula kwikhava yokukhusela i-argon yokuzalisa indlela yokukhusela, indlela yokukhusela i-argon yendawo yokukhusela, ukuzaliswa ngokuthe ngqo kwe-welding joint, indlela yokukhusela i-argon, njl njl.

1. Ikhava yokukhusela ezaliswe yindlela yokukhusela i-argon

Le ndlela isoloko isetyenziselwa i-welding yensimbi engenasici yamacwecwe kunye nemibhobho yobubanzi obukhulu.Isikhuselo sokukhusela sixhunyiwe kwipayipi yensimbi kunye ne-argon gas hose.I-valve yegesi ye-argon ivuliwe ukuze igcwalise isikhuselo sokukhusela ngegesi ye-argon.

Omnye umntu kufuneka abambe umbhobho wentsimbi njengesiphatho ukwenzela ukuba isigqubuthelo sokhuselo sityibilike kwidama elinyibilikisiweyo ngasemva ngolungelelwaniso kunye nokuwelda kwangaphandle kwepleyiti okanye umbhobho.

Ngale ndlela, icala elingasemva likhuselwe ngokufanelekileyo, kwaye ukukhuselwa kugxininiswe.Igesi ye-argon ayifuni ukuba ivulwe kakhulu, kwaye igesi ye-argon ichithwa ngaphantsi.

2. Ukhuseleko lokuzaliswa kwe-argon yendawo

Kulula ukusebenzisa ukhuseleko lwendawo kwimibhobho enendawo encinci yendawo kunye nemilinganiselo emifutshane.

Indlela: Vala i-welding edibeneyo yombhobho nge-tape (ukuthintela ukuvuza komoya).Vala iziphelo zombini zombhobho ngesipontshi, irabha, igobolondo lephepha, njl.Esinye isiphelo sombhobho sitywinwe kakuhle.Gqoka umngxuma omncinci (akukho mfuneko yesiponji), oya kuququzelela ukudibanisa i-welding yokugqibela kwaye ayiyi kubangela i-dents ngenxa yoxinzelelo olugqithisileyo lwangaphakathi.

Ngexesha le-welding, ukuze kuthintelwe isixa esikhulu segesi ye-argon ekukhutshweni kwi-weld seam, i-tape yokutywina kufuneka ikrazulwe kwaye idityaniswe kumacandelo, anokunciphisa ilahleko eyongezelelweyo yegesi ye-argon kwaye ikhusele ngokufanelekileyo i-weld seam.Iimpawu ziyachithwa, ukutshaja kwe-argon kucotha, ixabiso liphezulu kakhulu, njl.

3 .Indlela yokukhusela i-argon ngokuthe ngqo kwi-welding joint

Kwimibhobho emide kakhulu kwaye inobubanzi obuncinci, ukuzaliswa kwe-argon yendawo kukumosha kakhulu, umgangatho awunakuqinisekiswa, kwaye iindleko zeprojekthi ziphezulu kakhulu.Ukuze ugcine iindleko, indlela yokuzalisa i-argon ngokuthe ngqo kwi-joint welded ingasetyenziswa.

Indlela yokwenza iiplagi kumacala omabini e-weld seam

Yenza isiponji kwiplagi kunye nedayamitha enkulu kancinane kumbhobho kwaye udibanise amaqhekeza amabini esipontshi ngocingo kumgama we-300-400mm ukwenza iplagi ephindwe kabini.Esinye isiphelo seplagi siqhagamshelwe kwisiqwenga eside socingo lwentsimbi.

Xa udibana, beka iiplagi kwi-150-200mm kumacala omabini e-weld ukuba idityaniswe.Ucingo olude lwentsimbi kwelinye icala kufuneka lube lude kunobude bombhobho kwelinye icala le-weld kwaye luveze isiphelo sombhobho.Esinye isiphelo sombhobho omncinci wensimbi kufuneka sibekwe kwaye esinye isiphelo kufuneka sidibaniswe ne-argon hose.Faka isiphelo esisicaba kwi-weld ehambelanayo kwaye uyigcwalise nge-argon.Isalathiso esilungileyo sokufakwa sisona siphezulu, ukwenzela ukuba ngaphambi kokuba ukudibanisa kokugqibela kwe-weld ephantsi, ityhubhu encinci inokutsalwa kwaye idityaniswe yigesi eseleyo kumbhobho.Emva kwe-welding, sebenzisa ucingo ukukhupha iplagi.

Indlela yokukhusela iphepha elinyibilikayo emanzini

Ngaphambi kokuhlanganisana, ncamathelisa iphepha elinyibilikayo emanzini kwi-150-200mm kumacala omabini odibaniso lwe-welding njengetywina.Emva kokulungelelaniswa, sebenzisa indlela efanayo ye-welding ye-inflatable njengeplagi yesiponji.Xa umbhobho uvavanyelwa uxinzelelo lwe-hydraulic, iphepha elinyibilikayo ngamanzi liya kunyibilika kwaye likhutshwe ngamanzi.

4. Umgwebo wokukhusela igesi yeArgon

Impembelelo yokukhusela i-argon gas inokugwetywa ngokombala we-weld yangaphakathi, ukwenzela ukuba umqhubi unokulungelelanisa igesi ye-argon ngokombala ukufezekisa umphumo wokukhusela.Imibala imhlophe kunye negolide, kwaye ingwevu namnyama yeyona imbi.

5. Izilumkiso zoKhuseleko lweNsimbi eNgena-Stainless

(1) Ngaphambi kwe-argon arc welding, umva we-weldment kufuneka ukhuselwe ngokuwugcwalisa nge-argon kwangaphambili.Umyinge wokuhamba kufuneka ube mkhulu.Emva kokuba umoya ukhutshiwe, izinga lokuhamba liya kuncipha ngokuthe ngcembe.Ngethuba lenkqubo ye-welding, umbhobho kufuneka uzaliswe nge-argon ngokuqhubekayo.Umbhobho we-argon unokukhutshwa kuphela emva kokugqitywa kwe-welding ukwenzela ukuba i-weld ikhuselwe kakuhle.

Ukongezelela, ingqalelo ekhethekileyo kufuneka ihlawulwe kwinto yokuba i-welding inokuqhutywa kuphela emva kokuba umoya uphelile, ngaphandle koko umphumo wokukhusela wokuzaliswa kwe-argon uya kuchaphazeleka.

(2) Isantya sokuhamba kwegesi ye-argon kufuneka ifaneleke.Ukuba isantya sokuhamba sincinci kakhulu, ukukhuselwa akulungile, kwaye umva we-weld u-oxidized lula;ukuba izinga lokuhamba likhulu kakhulu, iziphene ezifana ne-concavity yengcambu ye-weld ziya kubangelwa, ezichaphazela umgangatho we-welding.

(3) I-argon gas inlet kufuneka ibekwe phantsi kangangoko kunokwenzeka kwicandelo elivaliweyo, kwaye umngxuma wokukhupha umoya kufuneka ubekwe phezulu kancinci kwicandelo lombhobho ovaliweyo.Ngenxa yokuba i-argon inzima kunomoya, ukuzalisa i-argon ukusuka kwindawo ephantsi kunokuqinisekisa ukuxinwa okuphezulu, kwaye umphumo wokukhusela wokuzaliswa kwe-argon uya kuba ngcono.

(4) Ukuze kuncitshiswe ilahleko yerhasi argon kumbhobho ukusuka umsantsa phakathi kwamalungu, nto leyo echaphazela isiphumo ukhuselo kunye nokwandisa iindleko, tape inokugxunyekwa ecaleni umsantsa phakathi kweendawo zokuwelda phambi kwewelding, ishiya ubude kuphela. enye eqhubekayo yokuwelda yi-welder, kunye nokususa iteyiphu ngelixa i-welding.

02

Indlela yokukhusela ucingo lwe-welding self-shielding

I-self-protected welding wire ngasemva yi-welding wire ene-coating.Ngexesha le-welding, i-coating yayo yokukhusela iya kuthatha inxaxheba ekukhuselweni okupheleleyo kwe-front and back of the pool etyhidiweyo, ukwenza i-dense layer ekhuselayo yokukhusela umva we-weld bead ekubeni i-oxidized.Olu luhlu lokukhusela luya kuwa ngokuzenzekelayo emva kokupholisa, kwaye luya kuhlanjululwa kwaye luvavanywe ngexesha lovavanyo loxinzelelo.iya kususwa.

Indlela yokusetyenziswa kolu hlobo lwentambo yokuwelda iyafana naleyo ye-argon ye-arc ye-arc ye-welding yocingo oluqinileyo, kunye nokusebenza kwentsimbi ye-weld inokuhlangabezana neemfuno.

I-self-protect welding wire ayikhawulelwanga kwiimeko ezahlukeneyo ze-welding, okwenza ukulungiswa kwe-welding ngokukhawuleza kwaye kulula.Nangona kunjalo, ngenxa yokugubungela kumphezulu wocingo lwe-welding, kuya kubakho ukuphazamiseka xa abasebenzi be-welding besebenza.

Ngenxa yokungahambelani kunye nobuchule be-welding obungafanelekanga kwi-coated welding ingcingo, iziphene ezifana ne-concavities ngamanye amaxesha zenzeka.Ngoko ke, kukho iimfuno ezithile zezakhono zokusebenza zabasebenzi kunye nobuchule bokusebenza.I-self-shielding wire isetyenziswe kakuhle kwii-primers ngenxa yeendleko zayo eziphezulu.

Ukongeza, kukho iibrendi ezininzi zeengcingo zokuzikhusela kwimarike ukukhetha kuzo, kwaye ukusetyenziswa kwazo kwahlukile.

Ixesha lokuposa: Sep-21-2023