Uxinzelelo olushiyekileyo lwe-welding lubangelwa ukusabalalisa ubushushu obungalinganiyo be-weldment ebangelwa yi-welding, ukwanda kwe-thermal kunye nokucutha kwe-weld metal, njl.

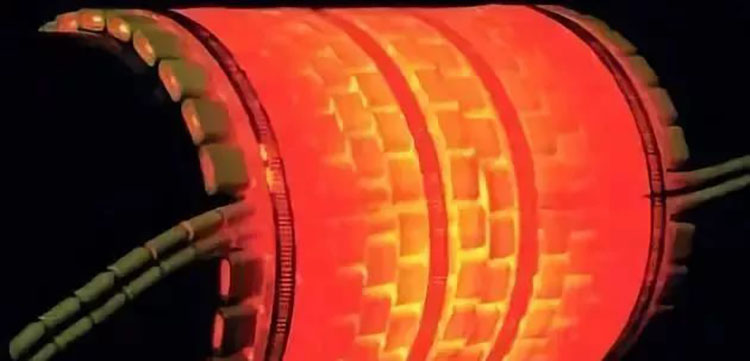

Eyona ndlela ixhaphakileyo yokuphelisa uxinzelelo olushiyekileyo lubushushu obuphezulu, oko kukuthi, ukufudumeza i-weld kubushushu obuthile kwaye uyibambe kangangexesha elithile kwiziko lonyango lobushushu, kwaye usebenzisa ukucutha umda wesivuno sezinto. kwiqondo lokushisa eliphezulu ukubangela ukuhamba kweplastiki kwiindawo ezinoxinzelelo oluphezulu lwangaphakathi.I-deformation ye-elastic iyancipha ngokuthe ngcembe, kwaye i-deformation yeplastiki inyuka ngokuthe ngcembe ukunciphisa uxinzelelo.

1.Ukukhetha indlela yokunyanga ukushisa

Isiphumo sonyango lobushushu be-post-weld kumandla okuqina kunye nomda wokukhasa wesinyithi unxulumene nobushushu bonyango lobushushu kunye nexesha lokubamba.Umphumo we-post-weld yonyango lokushisa kwimpembelelo yokuqina kwentsimbi ye-weld iyahluka ngeentlobo zetsimbi ezahlukeneyo.

Unyango lobushushu lwasemva kweweld luthatha ubushushu obuthile obuphezulu okanye obuqhelekileyo kunye nobushushu obuphezulu.Ukufumana i-gas welding joints, i-normalizing kunye neqondo lokushisa eliphezulu liyamkelwa.Oku kungenxa yokuba iinkozo ze-gas welding seam kunye nommandla ochaphazelekayo ngubushushu bunzima, kwaye iinkozo kufuneka zicocwe, ngoko ke unyango oluqhelekileyo luyamkelwa.

Nangona kunjalo, ukulinganisa okukodwa akukwazi ukuphelisa uxinzelelo olushiyekileyo, ngoko ke ukushisa okuphezulu kuyafuneka ukuphelisa uxinzelelo.Ubushushu obuphakathi obuphakathi bulungele kuphela ukudibanisa kunye nokuwelda kwezikhongozeli ezinkulu zentsimbi eziphantsi kwekhabhoni ezidityaniswe kwisiza, kwaye injongo yayo kukuphumeza ukupheliswa koxinzelelo oluyintsalela kunye ne-dehydrogenation.

Kwiimeko ezininzi, kusetyenziswa iqondo elinye lobushushu obuphezulu.Ukufudumeza kunye nokupholisa unyango lokushisa akufanele kube ngokukhawuleza, kwaye iindonga zangaphakathi nangaphandle kufuneka zifane.

2.Iindlela zokunyanga ukushisa ezisetyenziselwa kwiinqanawa zoxinzelelo

Kukho iintlobo ezimbini zeendlela zokunyanga ukushisa kwiinqanawa zoxinzelelo: enye yonyango lokushisa ukuphucula iimpawu zomatshini;enye i-post-weld heat treatment (PWHT).Ukuthetha ngokubanzi, unyango olushushu lwe-post-weld lunyango lobushushu lwendawo edibeneyo okanye amacandelo adibeneyo emva kokuba i-workpiece idityanisiwe.

Umxholo othile ubandakanya ukuphelisa uxinzelelo, ukuphelisa ngokupheleleyo, isisombululo esiluqilima, ukuqheleka, ukunyanzeliswa kunye nobushushu, ukuthoba, ukuthomalalisa uxinzelelo lobushushu obuphantsi, unyango lobushushu bemvula, njl.

Ngengqiqo emxinwa, unyango lobushushu emva kwe-weld lubhekiselele kuphela kuxinzelelo lwe-annealing, oko kukuthi, ukuze kuphuculwe ukusebenza kwendawo ye-welding kwaye kupheliswe iziphumo ezinobungozi ezifana noxinzelelo lwe-welding residual, ukwenzela ukutshisa ngokulinganayo kunye nokutshisa ngokupheleleyo indawo ye-welding. kunye neenxalenye ezinxulumene ngezantsi kwesigaba sentsimbi utshintsho 2 iqondo lokushisa, kwaye ke inkqubo yokupholisa iyunifomu.Kwiimeko ezininzi unyango lobushushu be-postweld ekuxoxwe ngalo lunyango lobushushu boxinzelelo lwe-postweld.

3.Injongo yonyango lwe-post weld heat

(1).Relax welding residual stress.

(2).Ukuzinzisa imilo kunye nobukhulu besakhiwo kunye nokunciphisa ukuphazamiseka.

(3).Ukuphucula ukusebenza kwesiseko sesinyithi kunye namalungu adityanisiweyo, kubandakanya:

a.Ukuphucula iplastiki yentsimbi ye-weld.

b.Ukunciphisa ukuqina kwendawo echaphazelekayo kubushushu.

c.Phucula ukuqina kokwaphuka.

d.Ukuphucula amandla okudinwa.

e.Ukubuyisela okanye ukwandisa amandla esivuno ancitshiswe ekubunjweni okubandayo.

(4).Ukuphucula ukukwazi ukumelana noxinzelelo lwe-corrosion.

(5).Ukukhupha ngakumbi iigesi ezinobungozi kwintsimbi edibeneyo, ngakumbi i-hydrogen, ukuthintela ukwenzeka kokuqhekeka okulibazisekayo.

4.Isigwebo semfuneko ye-PWHT

Ingaba unyango olushushu lwe-post-weld luyimfuneko kwisitya soxinzelelo kufuneka lucaciswe ngokucacileyo kuyilo, olufunwa yikhowudi yokuyila umkhumbi wangoku.

Kwimikhumbi yoxinzelelo oludibeneyo, kukho uxinzelelo olukhulu olushiyekileyo kwindawo ye-welding, kunye neziphumo ezibi zoxinzelelo olushiyekileyo.Kubonakaliswa kuphela phantsi kweemeko ezithile.Xa uxinzelelo olushiyekileyo ludibanisa ne-hydrogen kwi-weld, luya kukhuthaza ukuqina kwendawo echaphazelekayo kubushushu, okubangela ukuveliswa kweentanda ezibandayo kunye nokulibaziseka kweentanda.

Xa uxinzelelo lwe-static oluseleyo kwi-weld okanye uxinzelelo lomthwalo oguquguqukayo kumsebenzi womthwalo ludityaniswe nesenzo se-corrosion ye-medium, inokubangela i-crack corrosion, ebizwa ngokuba yi-corrosion yoxinzelelo.Uxinzelelo olushiyekileyo lwe-Welding kunye nesiseko sokuqina kwesinyithi okubangelwa yi-welding zizinto ezibalulekileyo zoxinzelelo lwe-corrosion cracking.

Iziphumo zophando zibonisa ukuba umphumo oyintloko wokuguqulwa kunye noxinzelelo oluseleyo kwizinto zetsimbi kukwenza utshintsho lwetsimbi ukusuka kwi-corrosion efanayo ukuya kwi-corrosion yendawo, oko kukuthi, kwi-intergranular okanye i-transgranular corrosion.Kakade ke, zombini i-corrosion cracking kunye ne-intergranular corrosion of metals zenzeka kwimidiya eneempawu ezithile zeso sinyithi.

Phambi koxinzelelo olushiyekileyo, yahlukile ngokokwakheka, ukuxinana kunye nobushushu bendawo etyiwayo, kunye nomahluko wokubunjwa, ubume, ubume bomhlaba, imeko yoxinzelelo, njl njl. , ukuze i-corrosion Ubume bomonakalo unokutshintsha.

5.Ukuqwalaselwa kwesiphumo esibanzi se-PWHT

Unyango lobushushu be-post-weld alunanzuzo ngokupheleleyo.Ngokubanzi, unyango lwe-post-weld heat heat lunenzuzo ekunciphiseni uxinzelelo olushiyekileyo, kwaye lwenziwa kuphela xa kukho iimfuno ezingqongqo zoxinzelelo lwe-corrosion.Nangona kunjalo, uvavanyo lwempembelelo yokuqina kwesampulu lubonisa ukuba unyango lobushushu lwasemva kwe-weld alulunganga kukuqina kwentsimbi egciniweyo kunye nendawo echatshazelwe bubushushu be-weld, kwaye ngamanye amaxesha ukuqhekeka kwe-intergranular kunokuthi kwenzeke ngaphakathi koluhlu lwenkozo yobushushu be-weld- indawo echaphazelekayo.

Ngaphaya koko, i-PWHT ixhomekeke ekwehlisweni kwamandla ezinto eziphathekayo kwiqondo lobushushu obuphezulu ukuphumeza isiqabu soxinzelelo.Ngoko ke, ngexesha le-PWHT, isakhiwo sinokulahlekelwa ukuqina.Kwizakhiwo ezithatha i-PWHT yonke okanye inxalenye, i-weldment kwiqondo lokushisa eliphezulu kufuneka ithathelwe ingqalelo phambi konyango lobushushu.amandla okuxhasa.

Ngoko ke, xa ucinga ukuba ngaba ukwenza unyango lobushushu emva kwe-weld, iingenelo kunye nokungonakali kunyango lobushushu kufuneka zithelekiswe ngokubanzi.Ukusuka kwimbono yokusebenza kwesakhiwo, kukho icala elinye lokuphucula ukusebenza, kunye nelinye icala lokunciphisa ukusebenza.Ugwebo olufanelekileyo kufuneka lwenziwe ngokusekelwe kuqwalaselo olubanzi lwale miba mibini.

Ixesha lokuposa: Jun-20-2023