Izakhono ezibizwa ngokuba yi-welding izakhono ziindlela ezilula ze-welding, i-angle echanekileyo ye-electrode kunye nokusebenza, kwaye ii-welds zakho aziyi kuba zibi kakhulu.

Ekuqaleni kwe-welding, ngenxa yokunqongophala kwe-welding rhythm kunye nobuchule bokuphatha obungenabuchule, kuya kubangela ikhefu.Ukuba inzulu kwaye ingaphantsi, iya kubangela kalula iipores, Ukubhala kuyafana, ukushaywa yi-stroke.

Iziphene ezininzi ze-welding:

1.I-undercut yangaphandle

Inkqubo yokuwelda iparameter ukhetho ayichanekanga okanye umsebenzi awukho umgangatho, ukuwelda kunye neendawo zentsimbi ezisisiseko zokubunjwa kwe-groove okanye ukudakumba, eyaziwa ngokuba ngumphetho wokuluma.(Ekuqaleni ukuwelda kuba andazi ubungakanani ukungazinzi yangoku kunye welding isandla kulula ukuba kubangele ukuluma, ukuthintela ukuluma kukuqhelisela ubuchule ukuwelda, kufuneka uzinzile, musa ukuba nexhala.)

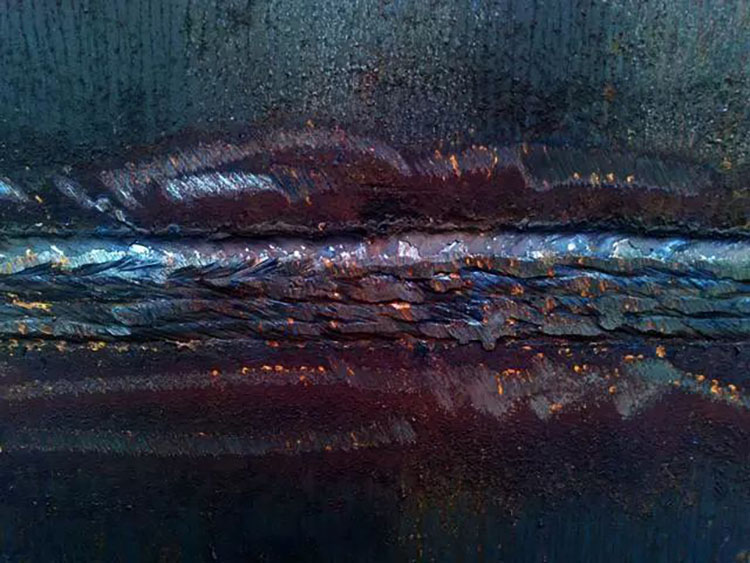

Lo ngumfanekiso we-undercut

2.Stomata

Ngexesha lokuwelda, igesi ekwidama elinyibilikisiweyo ayiphumi xa iqina ize ihlale kwi weld yenze umngxuma, obizwa ngokuba yiporosity.(Ekuqaleni kwe-welding, ngenxa yokungakwazi ukubamba isigqi se-welding kunye nokuphathwa ngokungenabuchule kwemichilo, kuya kubangela ikhefu. Ukuba inzulu kwaye incinci, iya kubangela ama-pores ngokulula. I-calligraphy kunye nokubhala kuyafana, enye ukubetha ngexesha.)

Lo ngumngxuma womoya we-welding

3.Ayingenwanga, ayidityaniswanga

Kukho izizathu ezininzi zokungenwa okungaphelelanga kunye nokufakwa, njenge-gap encinci ye-weld okanye i-angle ye-groove, i-edge enzima kakhulu, i-electrode diameter enkulu, isantya esikhawulezayo se-welding okanye i-arc ende, njl. ukuchatshazelwa kukungcola kwi-groove, kwaye ukungcola okunganyibilikiyo kunokuchaphazela umphumo wokudibanisa weld.

(Lawula kuphela isantya se-welding, yangoku kunye nezinye iiparameters zenkqubo ngexesha le-welding, khetha ngokuchanekileyo ubungakanani be-groove, kwaye ususe isikali kunye nokungcola ebusweni be-groove; ingcambu ye-welding ye-back cover kufuneka ihlambuluke ngokucokisekileyo.)

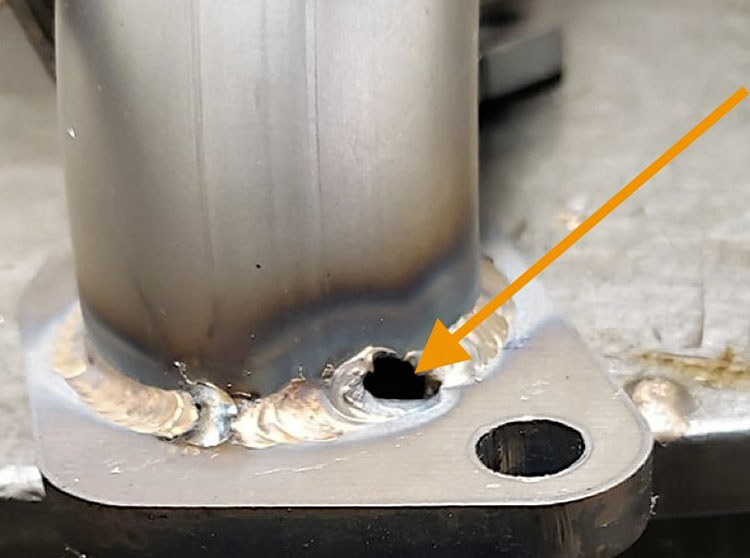

Ukungena okungaphelelanga

4.Burn ngapha

Ebudeni benkqubo yokuwelda, isinyithi esinyibilikisiweyo siphuma ngasemva kumjelo, senze isiphene esinemingxuma esibizwa ngokuba yi-burn-through.(Indlela yokuthintela kukunciphisa umsinga kunye nokunciphisa umsantsa we-weld)

Imifanekiso yeWelding iyatshisa

5.Ubuso be-welding engabonakaliyo

Iziphene ezifana ne-lapping kunye ne-serpentine bead zonke zibangelwa yisantya esicothayo se-welding kunye ne-welding ephantsi kakhulu yangoku.(Indlela yokuthintela kukuqhelisela ngakumbi kwaye ubambe isantya esifanelekileyo sokuwelda. Abantu abaninzi baya kukwenza oku ekuqaleni, baziqhelanise ngakumbi.)

Ukuwelda kwenyoka

i-lap welding

Ixesha lokuposa: May-31-2023