Umthombo wamandla wokubrawuza unokuba bubushushu bokusabela kweekhemikhali okanye ubushushu obungathanga ngqo.Isebenzisa isinyithi esinendawo yokunyibilika engaphantsi kunento enokuthi idityaniswe njenge-solder.Emva kokufudumeza, i-solder iyanyibilika, kwaye isenzo se-capillary sityhalela i-solder kwisithuba phakathi kweendawo zoqhagamshelwano zokudibanisa ukumanzisa ubuso bentsimbi ukuba idityaniswe ukwenzela ukuba isigaba solwelo kunye nesigaba esiqinileyo sihlukaniswe.Ukudibanisa phakathi kwezigaba ukwenza i-joint brazed.Ngoko ke, ukubethelwa yindlela ye-welding yesigaba esiqinileyo kunye nesigaba se-liquid.

1. Iimpawu kunye nokusetyenziswa kwebrazing

I-Brazing isebenzisa i-alloy enendawo yokunyibilika engaphantsi kunesiseko sesinyithi njenge-solder.Xa ishushu, i-solder iyanyibilika kwaye izalise kwaye ihlale kwisithuba esidibeneyo ngokumanzisa kunye nesenzo se-capillary, ngelixa isiseko sesinyithi sikwimeko eqinileyo, sixhomekeke kwi-solder engamanzi kunye nesiseko esiqinileyo Ukudibanisa phakathi kwezinto zenza i-brazed joint.I-Brazing inefuthe elincinci kwiipropati zomzimba kunye neekhemikhali zesiseko sesinyithi, uxinzelelo oluncinci lwe-welding kunye ne-deformation, inokuthi idibanise iintsimbi ezingafaniyo ezinomahluko omkhulu kwiipropati, inokugqiba ii-welds ezininzi ngaxeshanye, imbonakalo yokudibanisa intle kwaye icocekile, isixhobo silula, kwaye utyalo-mali lwemveliso luncinci.Nangona kunjalo, i-brazed joint inamandla aphantsi kunye nokunganyangeki kobushushu.

Izicelo: Izixhobo zokusika i-Carbide, i-drilling bits, iifreyimu zebhayisikili, i-heat exchangers, i-conduits kunye nezixhobo ezahlukeneyo, njl.;ekwenziweni kwee-microwave waveguides, iityhubhu ze-electron kunye nezixhobo ze-electronic vacuum, ukubrawuza yeyona ndlela yokudibanisa enokwenzeka.

2.Intsimbi yokutshisa kunye ne-flux

I-brazing filler metal yintsimbi yokuzalisa eyenza intloko yokuqhafaza, kunye nomgangatho wentloko yokuqhafaza kuxhomekeke kwintsimbi yokuqhafaza ukuya kwinqanaba elikhulu.Intsimbi yokuzalisa kufuneka ibe neyona ndawo ifanelekileyo yokunyibilika, ukumanzisa okulungileyo kunye nokukwazi ukukhupha, kunokusasazeka kunye nesiseko sesinyithi, kwaye kufuneka sibe neempawu ezithile zomatshini kunye neempawu zomzimba kunye neekhemikhali ukuhlangabezana neemfuno zokusebenza komdibaniso.Ngokwendawo yokunyibilika eyohlukeneyo yentsimbi yokuzalisa ibrazing, ibrazing inokwahlulwa ibe ngandidi ezimbini: ibrazing soft and hard brazing.

(1) Ukukhanyiswa okuthambileyo.Ibrazing enendawo yokunyibilika engaphantsi kwe-450 ° C ibizwa ngokuba yi-soft brazing, kwaye isinyithi esiqhelekileyo esisetyenziswayo sokuzalisa intsimbi yi-tin lead brazing, enokumanzisa okuhle kunye nokuhamba kombane kwaye isetyenziswa kakhulu kwiimveliso ze-elektroniki, izixhobo zemoto kunye neendawo zemoto.Amandla odibaniso olwe brazed ngokuqhelekileyo yi 60 ~ 140MPa.

(2) Ukutshisa.I-Brazing ene-melting point ephezulu kune-450 ° C ibizwa ngokuba yi-brazing, kunye nezixhobo eziqhelekileyo zokubhobhoza zibhedu kunye neziseko zesilivere.Umdibaniso onesiseko sentsimbi yesilivere unamandla aphezulu, ukuhanjiswa kombane kunye nokumelana nokugqwala, indawo yokunyibilika yentsimbi yokuzalisa iphantsi, kwaye inkqubo ilungile, kodwa ixabiso letsimbi yokuzalisa liphezulu, kwaye lisetyenziswa kakhulu ukuwelda. iindawo ezineemfuno eziphezulu.I-Brazing isetyenziswa kakhulu kwintsimbi kunye ne-copper alloy workpieces enamandla amakhulu, kunye nezixhobo zokuqhayisa.Amandla adibeneyo adibeneyo angama-200 ~ 490MPa,

Qaphela: Indawo yoqhagamshelwano yesiseko kufuneka icoceke kakhulu, ngoko ke kufuneka kusetyenziswe i-flux.Indima ye-flux kukususa i-oxide kunye nokungcola kwe-oyile kumphezulu wesiseko sesinyithi kunye nentsimbi yokuzalisa, ukukhusela indawo yokudibanisa yentsimbi yokuzalisa kunye nesiseko sesinyithi kwi-oxidation, kunye nokwandisa ukumanzi kunye ne-capillary fluidity ye-filler. intsimbi.Indawo yokuncibilika kwe-flux kufuneka ibe ngaphantsi kuneyentsimbi yokuzalisa, kunye ne-corrosion ye-residu ye-flux kwisiseko sesinyithi kunye namalungu kufuneka abe ngaphantsi.I-brazing flux eqhelekileyo yi-rosin okanye i-zinc chloride isisombululo, kunye ne-brazing flux eqhelekileyo ngumxube we-borax, i-boric acid kunye ne-alkaline fluoride.

Ngokwemithombo eyahlukeneyo yobushushu okanye iindlela zokufudumeza ibrazing inokwahlulwa ibe:ukuvutha komlilo, ukunyanzeliswa kwe-induction, ukuvutha kwesithando somlilo, i-dip brazing, i-resistance brazing kunye nokunye.Ngenxa yokuba ubushushu bokufudumala buphantsi kakhulu ngexesha lokugcoba, kunempembelelo encinci ekusebenzeni kwezinto zokusebenza, kunye noxinzelelo loxinzelelo lwe-weldment luncinci.Nangona kunjalo, amandla edibeneyo edibeneyo aphantsi ngokubanzi, kwaye ukumelana nobushushu kubi.

Indlela yokufudumeza ibrazing:Phantse yonke imithombo yokufudumeza ingasetyenziselwa njengemithombo yokushisa yokutshisa, kwaye ngokutsho kolu luhlu luhlelwa.

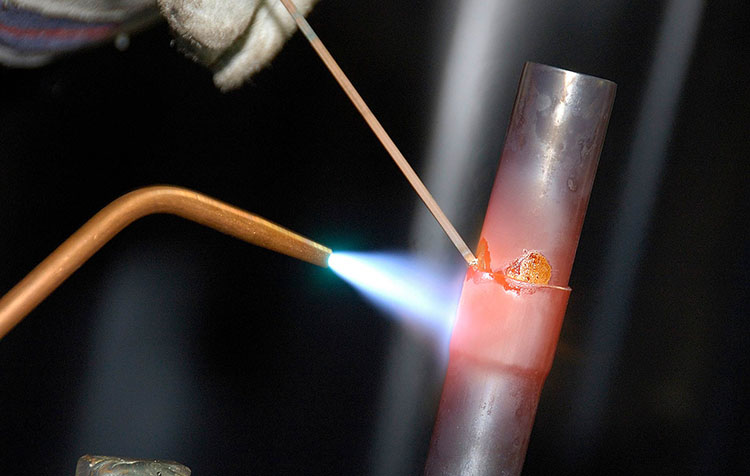

Ukuvutha komlilo:ukufudumeza nge-gas flame, esetyenziselwa i-carbon steel, i-stainless steel, i-carbide, i-iron cast, i-alloys yobhedu kunye nobhedu, i-aluminium kunye ne-aluminium alloy brazing.

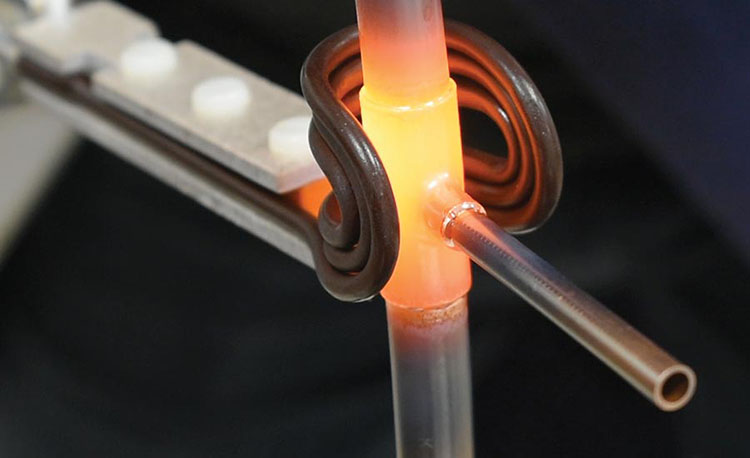

I-induction brazing:Ukusetyenziswa kwemimandla yamagnetic etshintshanayo ukuvelisa i-current induced current kwinxalenye yokumelana nobushushu be-welding ye-welding, kwi-symmetrical shape ye-welding, ngokukodwa ukubethelwa kwe-shaft yombhobho.

Dip brazing:inxalenye welding ngokuyinxenye okanye ngokupheleleyo kuntywiliselwa kumxube ityuwa etyhidiweyo okanye solder ukunyibilika, sithembele ubushushu ezi media elulwelo ukufikelela inkqubo yokuqhotsa, nto leyo ebonakala ukufudumeza ngokukhawuleza, ubushushu efanayo, deformation encinane welding inxalenye.

Ukunyanyiswa kwesithando somlilo:I-welds ifudumeza isithando somlilo, esinokukhusela i-welds ngokucoca okanye ukusebenzisa iigesi zokunciphisa okanye ezingenayo.

Ukongeza, kukho i-soldering iron brazing, ukumelana nokunyanyiswa, ukunyanyiswa kwe-diffusion, i-infrared brazing, i-reaction brazing, i-electron beam brazing, i-laser brazing, njl.

I-Brazing ingasetyenziselwa ukuwelda intsimbi yekhabhoni, insimbi engagqwali, i-superalloy, i-aluminiyam, ubhedu kunye nezinye izinto zetsimbi, kwaye inokudibanisa isinyithi esingafaniyo, isinyithi kunye nezingezizo.Ifaneleka kwi-welding joints kunye nomthwalo omncinci okanye ukusebenza kwindawo yokushisa, ngokukodwa ifanelekileyo ngokuchanekileyo, i-micro kunye ne-complex ye-welds multi-brazed welds.

Ixesha lokuposa: Jul-06-2023