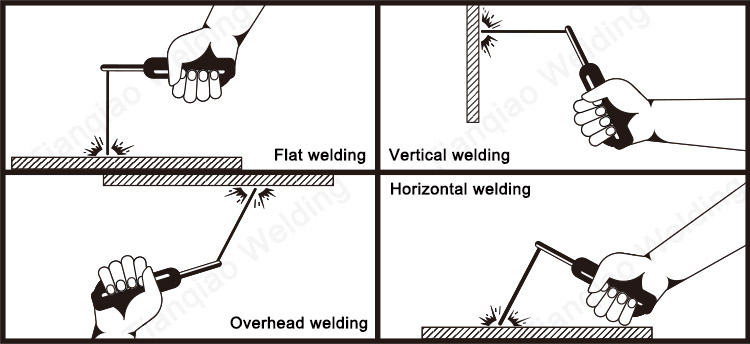

Isikhundla se-welding sibhekiswa xa sithungela, indawo ehambelana nendawo ye-weld kwi-welder.

Umzobo 1. Tianqiao welding positon

Umzobo 1. Tianqiao welding positon

Kukho ukuwelda okusicaba, ukuwelda okuthe tye, ukuwelda okuthe nkqo kunye nokuwelding ngaphezulu.Ukuwelda kweFlat kubhekisa kwi-welding ethe tyaba eyenziwa ngumshicileli ethobe intloko, ngoko ikwabizwa ngokuba yi-downhand welding;ukudibanisa kwi-T-shaped weldment, i-weldment emilise okwe-T idla ngokubekwa kwi-45 ° ukwenza indawo ye-welding ye-welding seam ezantsi, ebizwa ngokuba yi-ship welding.I-welding ethe tyaba ibhekisa kwi-welding ethe tyaba eyenziwa ngumtshisi malunga nobude obufanayo nengalo.I-welding ethe nkqo ibhekisa kwi-welding esezantsi ukuya phezulu.Ukuwelda ngaphezulu kubhekiselele kwiwelding yomthungo ethe tyaba eyenziwa ngumshicileli ejonge phezulu.I-Flat welding yeyona nto ilula kakhulu ekuqinisekiseni umgangatho we-welding, i-welding ethe tyaba iyeyesibini, i-welding ethe nkqo iyeyesithathu, kwaye i-overhead welding yeyona nto inzima kakhulu ekuqinisekiseni umgangatho kwaye kufuneka igwenywe kangangoko kunokwenzeka.

Umzobo 2. Tianqiao welding flat

Umzobo 2. Tianqiao welding flat

Ukuwelda okucaba

Iimpawu ze-welding ye-welding flat:

1. Intsimbi enyibilikayo ixhomekeke ubukhulu becala kubunzima bayo ekutshintsheni kwidama elinyibilikisiweyo.

2. Ubume kunye nentsimbi yedama elityhidiweyo kulula ukuyigcina nokulawula.

3. Kwiintsimbi ze-welding ezinobunzima obufanayo, i-welding yangoku kwindawo ye-welding flat inkulu kunezinye izikhundla ze-welding, kunye nokusebenza kakuhle kwemveliso kuphezulu.

4. I-slag kunye ne-pool etyhidiweyo ilungele ukuxuba, ngakumbi xa i-welding flat fillet welds, i-slag ilula ukukhokela kunye nokwenza ukufakwa kwe-slag.

*Akukho lula ukwahlula i-slag ye-asidi ye-welding intonga kwi-pool etyhidiweyo;ezimbini zealkaline welding rods zicace noko;umgangatho we-HG20581 uchaza ngokucacileyo ukuba i-acid welding rods ayikwazi ukusetyenziswa kwi-Class II kunye ne-III iinqanawa.

5. Iiparamitha ze-welding ezingafanelekanga kunye nokusebenza kunokukhokelela ngokulula kwiziphene ezifana ne-weld bead, i-undercut, kunye ne-welding deformation.

6. Xa i-back side ye-single-side welding yenziwa ngokukhululekileyo, i-weld yokuqala ixhomekeke kwiinkqubo zokungena ezingalinganiyo kunye nokubumba okungahambi kakuhle.

Iindawo zokuwelda kwi-flat welding:

1. Ngokutsho kobunzima beplate, i-electrode enkulu yobubanzi kunye ne-welding current enkulu ingasetyenziswa.

2. Xa i-welding, intonga ye-welding kunye ne-weldment yenza i-angle ye-60 ~ 80 °, kwaye ukuhlukana kwe-slag kunye nesinyithi se-liquid kulawulwa ukukhusela i-slag ukuba ingabonakali kwangaphambili.

3. Xa ubukhulu bepleyiti bungaphantsi okanye bulingana ne-6mm, ukuwelda kwe-butt flat ngokuqhelekileyo kunohlobo lwe-groove, kwaye i-welding seam yangaphambili kufuneka ibe yi-short-arc welding kunye ne-electrode φ3.2 ~ 4, kunye nobunzulu bokungena ukufikelela kwi-2/3 yobukhulu beplate;ngaphambi kokuba umva utywinwe, akuyimfuneko ukuhlambulula iingcambu (ngaphandle kwezakhiwo ezibalulekileyo), kodwa i-slag kufuneka ihlambuluke kwaye ikhoyo ingaba nkulu.

4. Ukuba kukho ukuxutywa okungacacanga kwe-slag kunye nesinyithi se-pool etyhidiweyo kwi-butt flat welding, i-arc inokunyuswa, i-electrode inokunyuswa phambili, kwaye i-slag etyhidiweyo inokutyhalwa ngasemva kwechibi elityhidiweyo ukukhusela ukufakwa kwe-slag.

5. Xa udibanisa i-welds inclined at horizontally, i-upslope welding kufuneka isetyenziswe ukukhusela ukufakwa kwe-slag kunye ne-pool etyhidiweyo ekuqhubeleni phambili ukuphepha ukufakwa kwe-slag.

6. Xa usebenzisa i-multi-layer kunye ne-multi-pass welding, qwa lasela inani le-welding passes kunye nokulandelelana kwe-welding, kwaye uluhlu ngalunye alufanele lube ngaphezu kwe-4 ~ 5mm.

7. Kwi-flat-angle welded joints of T, i-joint joint, kunye ne-overlap joint, ukuba ubukhulu bamacwecwe amabini ahlukeneyo, i-angle yentonga ye-welding kufuneka ihlengahlengiswe ukuphambukisa i-arc kwelinye icala le-plate eshinyeneyo, ukuze amacwecwe amabini afudunyezwe ngokulinganayo.

8. Ukhetho oluchanekileyo lwendlela yokuthumela

(1) Xa ubukhulu be-welding bungaphantsi okanye bulingana ne-6mm, chwetheza u-I groove butt welding flat.Xa i-welding emacala amabini yamkelwe, i-welding seam yangaphambili ithatha umgca othe tye, ohamba kancinci;i-welding seam yangasemva ithatha umgca othe tye, kwaye i-welding current inkulu kancinane., Ngesantya.

(2) Xa ubukhulu beplate ≤6mm, xa uvula ezinye iifom ze-grooves, i-welding multi-layer okanye i-multi-layer multi-pass welding ingasetyenziswa.Uluhlu lokuqala lwe-welding ephantsi kufuneka lusebenzise i-electrode yangoku encinci, i-standard standard yangoku, umgca ochanekileyo okanye i-sawtooth.Ukuwelda ibha yezothutho yemilo.Ukuzalisa i-welding ye-layer, i-electrode enkulu ye-diameter kunye ne-arc i-welding emfutshane kunye ne-welding current enkulu inokukhethwa.

(3) Xa ubukhulu bomlenze we-flat fillet welding ye-T-joint ingaphantsi kwe-6mm, i-welding eyodwa-layer ingasetyenziswa, kwaye i-linear, i-oblique ring okanye indlela yokuthutha e-zigzag ingasetyenziswa;xa ubukhulu bomlenze bukhulu, i-welding multi-layer okanye i-multi-layer welding kufuneka isetyenziswe.I-Multi-pass welding, i-welding ephantsi ithatha indlela yokuthutha i-linear strip, kwaye umaleko wokuzalisa ungakhetha i-oblique sawtooth okanye i-oblique circular strip transport.

(4) Ngokuqhelekileyo, i-multi-layer kunye ne-multi-pass welding kufuneka idityaniswe yindlela yokuthutha yomgca othe ngqo.

Ii-electrode zentsimbi ezithambileyo ezifanelekileyo kwi-welding flat areAWS E6013, AWS E6010, AWS E6011, AWS E7018.

Umzobo 3. Tianqiao welding nkqo

Umzobo 3. Tianqiao welding nkqo

Ukuwelda ngokuthe nkqo

Iimpawu ze-welding ye-welding ethe nkqo:

1. Isinyithi se-pool etyhidiweyo kunye ne-slag etyhidiweyo ziwa ngenxa yobunzima bazo kwaye kulula ukuhlukana.

2. Xa iqondo lobushushu lechibi elinyibilikisiweyo liphezulu kakhulu, isinyithi sechibi esityhidiweyo silula ukuba sithobe phantsi ukuze senze iziphene ezifana ne-weld bead, i-undercut, ukufakwa kwe-slag, njl., kunye ne-weld ayilingani.

3. Ingcambu ye-T-joint weld kulula ukwenza ukungena okungaphelelanga.

4. Iqondo lokungena kulula ukulibamba.

5. Imveliso ye-Welding iphantsi kune-flat welding.

Amanqaku aphambili ewelding ethe nkqo:

1. Gcina i-angle yentonga ye-welding echanekileyo;

2. Kwimveliso, i-welding i-vertical vertical welding isetyenziswa ngokuqhelekileyo, kwaye i-welding vertical vertical idinga iintonga ezikhethekileyo ze-welding ukuqinisekisa umgangatho we-weld.I-welding yangoku kwi-vertical up welding yi-10 ~ 15% encinci kunaleyo ye-flat welding, kunye ne-electrode encinci ye-diameter (<φ4mm) kufuneka ikhethwe.

3. Sebenzisa i-arc welding emfutshane ukunciphisa umgama ukusuka kwithontsi ukuya kwidama elinyibilikisiweyo.

4. Sebenzisa indlela yokuthumela echanekileyo.

(1) I-T-groove butt joint (edla ngokusetyenziselwa amacwecwe amancinci) xa i-welding ethe nkqo yenziwa, i-linear, i-zigzag, i-crescent-shaped strip welding isetyenziswa ngokuqhelekileyo, kwaye ubude be-arc ubude abukho ngaphezu kwe-6mm.

(2) Xa uvula ezinye iindlela zokuwelda okuthe nkqo kwe-groove butt, umaleko wokuqala we weld uhlala udityaniswa ngewelding eyaphukileyo, emile okwe crescent kunye ne-triangular-shaped welding ngokujingi okuncinci.Emva kwexesha, umaleko ngamnye ungasetyenziselwa i-crescent okanye i-zigzag striping.

(3) Ngexesha le-welding ethe nkqo yee-joints ezimilise okwe-T, intonga ye-welding kufuneka ibe nexesha elifanelekileyo lokuhlala kumacala omabini kunye neekona eziphezulu ze-welding seam, kunye ne-swing amplitude ye-welding intonga akufanele ibe mkhulu kunobubanzi be-welding. umthungo.Ukusebenza kwentonga ye-welding kuyafana nenye i-welding ethe nkqo ene-grooves.

4Imicu emile okweCrescent ingasetyenziselwa ukuwelda iindawo zomthungo ezineemfuno eziphezulu;imicu egoso-goso ingasetyenziselwa imiphezulu ethe tyaba (imilo ye-concave embindini inxulumene nexesha lokunqumama).

Ii-electrode zensimbi ezithambileyo ezifanelekileyo kwi-welding ethe nkqoAWS E6013, AWS E6010, AWS E6011, AWS E7018, ngakumbiE6011ifanelekile kwiwelding ethe nkqo phezulu-ezantsi.

Umzobo 4. Tianqiao ukuwelda ngaphezulu

Ukuwelda ngaphezulu

Iimpawu ze-welding ye-welding ephezulu:

1. Intsimbi etyhidiweyo iyawa ngenxa yomxhuzulane, kwaye imilo kunye nobukhulu bedama elityhidiweyo akufanele lilawulwe.

2. Kunzima ukuthutha umgca, kwaye umphezulu we-weldment awufanelekanga ukudibanisa.

3. Iziphene ezifana nokufakwa kwe-slag, ukungena okungaphelelanga, i-weld bead kunye nokwakheka okungahambi kakuhle kwe-weld kulula ukubonakala.

4. Isinyithi esityhidiweyo sitshiza kwaye sisasazeke, nto leyo enokubangela iingozi ezivuthayo.

5. Ukusebenza kwe-welding ephezulu kuphantsi kunezinye izikhundla.

Iindawo zokuwelda zokuwelda ngaphezulu:

1. Ukuwelda ngaphezulu kweewedi zeempundu.Xa ubukhulu be-weldment bungaphantsi okanye bulingana ne-4mm, sebenzisa i-grooves yohlobo lwe-I kwaye usebenzise i-φ3.2mm iintonga ze-welding kunye ne-moderate welding current;xa ubukhulu be-welding bukhulu okanye bulingana ne-5mm, i-multi-layer kunye ne-multi-pass welding kufuneka isetyenziswe.

2. Umthungo we-welding we-T-shaped joint welding overhead.Xa unyawo lwe-welding lungaphantsi kwe-8mm, kufuneka kusetyenziswe i-welding enye, kwaye xa unyawo lwe-welding lukhulu kune-8mm, kufuneka kusetyenziswe i-multi-layer kunye ne-multi-pass welding.

3. Ngokwemeko ethile, yamkela indlela echanekileyo yokuthumela ngenqanawa:

(1) Xa ubungakanani bonyawo lwe-welding luncinci, uhlobo oluhambelanayo okanye oluhambelanayo lusetyenziselwa ukugqiba i-welding enye;xa ubungakanani beenyawo ze-welding zikhulu, i-welding ye-multi-layer okanye i-multi-layer multi-pass welding ingasetyenziswa, kwaye umaleko wokuqala kufuneka usetyenziswe ukuthutha umgca ochanekileyo, ezinye iileyile zinokukhetha unxantathu oblique okanye indlela yokuthutha i-oblique ring.

(2) Kungakhathaliseki ukuba yeyiphi indlela yokuthutha eyamkelweyo, intsimbi ye-weld akufanele ibe yinto eninzi kakhulu xa idlula kwi-pool etyhidiweyo.

Ii-electrode zentsimbi ezithambileyo ezifanelekileyo ukuwelda ngaphezuluAWS E6013, AWS E6010, AWS E6011, AWS E7018

Umzobo 5. Tianqiao welding oxwesileyo

Umzobo 5. Tianqiao welding oxwesileyo

welding Horizontal

Iimpawu zeWelding ye-welding ethe tyaba:

1. Isinyithi esityhidiweyo siwela ngokulula kwi-groove ngenxa yobunzima bayo, ibangela iziphene eziphantsi kwe-undercut kwicala eliphezulu, kunye ne-weld bead emise okwe-teardrop okanye iziphene zokungena ezingaphelelanga kwicala elingezantsi.

2. Isinyithi esityhidiweyo kunye ne-slag kulula ukuhlukana, kuncinci njenge-welding ethe nkqo.

Amanqaku aphambili e-welding ethe tyaba:

1. Imijelo ye-welding ethe tyaba yeempundu idla ngokumilise okwe-V okanye imile okwe-K, amalungu empundu anobunzima bepleyiti obuyi-3 ~ 4mm anokudityaniswa macala omabini ngohlobo lwegrooves yohlobo lwe-I.

2. Sebenzisa intonga yokudibanisa i-diameter encinci, i-welding current incinci kune-welding flat, ukusebenza kwe-arc emfutshane, kunokulawula ngcono ukuhamba kwesinyithi esityhidiweyo.

3. Xa udibanisa iipleyiti ezityebileyo, ukongeza kwi-weld esezantsi, kuyacetyiswa ukuba usebenzise i-multi-layer kunye ne-multi-pass welding.

4. Kwi-welding ye-multi-layer kunye ne-multi-pass welding, ingqwalasela ekhethekileyo kufuneka ihlawulwe ekulawuleni umgama we-overlap phakathi kwe-weld pass.Kwi-welding nganye ye-welding, qalisa i-welding kwi-1/3 ye-weld yangaphambili ukukhusela ukungalingani.

5. Ngokwemeko ethile, gcina i-angle ye-welding rod eyiyo, kwaye isantya se-welding kufuneka sibe yi-blocky encinci kunye neyunifomu.

6. Sebenzisa indlela yokuthumela echanekileyo.

(1) Kudidi lwe-I butt welding ethe tyaba, kungcono ukusebenzisa indlela ye-reciprocating linear strip ye-welding seam yangaphambili;imicu eqondileyo okanye encinci ye-oblique setyhula kufuneka isetyenziswe kwiindawo ezityebileyo, kunye nemicu ethe tye ngasemva, kunye ne-welding current inokwandiswa ngokufanelekileyo.

(2) Sebenzisa enye i-bevel butt welding ethe tyaba.Xa i-gap incinci, i-welding ephantsi ingasebenzisa imicu ethe tye;xa umsantsa mkhulu, umaleko ongezantsi wamkela imicu ephindaphindanayo;xa ezinye iileya ziyi-welding ye-multi-layer, i-strip inclined strip ingasetyenziswa.Ukuthuthwa komgca ochanekileyo kufuneka kusetyenziswe ukuthuthwa kweesetyhula kunye ne-multi-layer kunye ne-multi-pass welding.

Ii-electrode zensimbi ezithambileyo ezifanelekileyo kwi-welding ethe tyabaAWS E6013, AWS E6010, AWS E6011, AWS E7018

Ixesha lokuposa: Jul-21-2021