Ukugquma kudlala i-metallurgical reaction entsonkothileyo kunye notshintsho lomzimba kunye neekhemikhali kwinkqubo ye-welding, eyoyisa ngokusisiseko iingxaki kwi-welding ye-electrode yefoto, ngoko ke ukwambathisa ngomnye wemiba ephambili yokumisela umgangatho wentsimbi ye-weld.

Ukwalekwa kwe-Electrode:Kubhekiselele kumaleko wokugquma wezinto ezicolekileyo zegranular ezineempawu ezahlukeneyo zomzimba kunye neekhemikhali eziqatywe ngokulinganayo kumphezulu we-welding core.

Indima yei-electrode ye-weldingukutyabeka:Kwinkqubo ye-welding, yenza i-slag enendawo yokunyibilika efanelekileyo, i-viscosity, ingxinano, i-alkalinity kunye nezinye iimpawu zomzimba kunye neekhemikhali, ukuqinisekisa ukutsha kwe-arc okuzinzileyo, ukwenza i-droplet metal iguqule ngokulula, ukudala umoya ojikeleze indawo ye-arc kunye ne-pool etyhidiweyo ukukhusela. indawo yokuwelda, kwaye ufumane ukubunjwa okuhle kunye nokusebenza kakuhle.Ngokudibanisa i-deoxidizer, i-alloying element okanye umxholo othile we-iron powder kwi-coating, inokuhlangabezana neemfuno zokusebenza kwe-weld metal okanye ukuphucula ukusebenza kakuhle kokunyibilika.

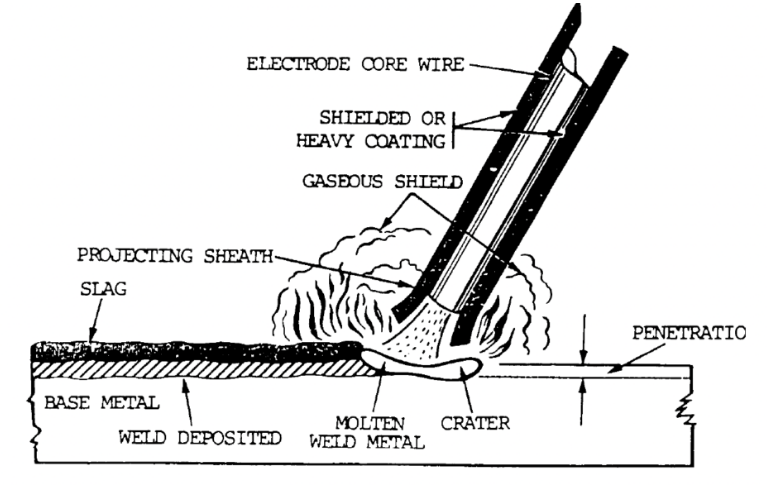

Umgaqo we-electrode arc welding:

1. Ulusu lweyeza

2. Weld core

3. Khusela igesi

4: Arc

5. Idama elityhidiweyo

6. Izinto ezisisiseko

7. Weld

8. Welding slag

9. I-Slag

10. Nyibilika amathontsi

Izinto ezahlukeneyo eziluhlaza ngokwendima yazo kwi-electrode coating inokwahlulwa ibe:

(1) I-arc stabilizer

Umsebenzi oyintloko kukwenza i-electrode ibe lula ukuqala i-arc kwaye igcine ukutshisa okuzinzile kwe-arc kwinkqubo ye-welding.Njengoko i-arc stabilizer imathiriyeli ekrwada ubukhulu becala ezinye ziqulethe inani elithile le-ionization ephantsi enokubakho ngokulula i-ionizing element, ezifana ne-feldspar, i-sodium silicate, i-rutile, i-titanium dioxide, i-marble, i-mica, i-ilmenite, i-ilmenite encitshisiweyo njalo njalo.

(2) I-arhente yokwenza igesi

Ngaphantsi kwesenzo sokushisa okuphezulu kwe-arc ukubola kwegesi, ukwenza umoya okhuselayo, ukukhusela i-arc kunye nesinyithi esityhidiweyo, ukukhusela ukungena kwe-oksijini kunye ne-nitrogen emoyeni ojikelezayo.Ngokuqhelekileyo i-gas-making agents isetyenziselwa i-carbonate (njenge-marble, i-dolomite, i-rhombic acid, i-barium carbonate, njl.) kunye ne-organic matter (efana nomgubo womthi, isitashi, i-cellulose, i-resin, njl.).

(3) I-Deoxidizer (eyaziwa ngokuba yi-arhente yokunciphisa)

Umxholo we-oksijini kwi-weld metal ungancitshiswa kwaye ukusebenza kwentsimbi ye-weld kunokuphuculwa nge-chemical metallurgical reaction kwinkqubo ye-welding.I-deoxidizer iqulethe izinto ze-iron alloy kunye nomgubo wesinyithi kunye nobudlelwane obukhulu be-oksijini.I-deoxidizer esetyenziswa ngokuqhelekileyo yi-ferromanganese, i-ferrosilicon, i-ferrotitanium, i-ferroaluminum, i-silicon calcium alloy, njl.

(4) Iplastiki

Umsebenzi oyintloko kukuphucula iplastiki, i-elasticity kunye ne-fluidity kwinkqubo ye-electrode coating coating, ukuphucula umgangatho wokugquma we-electrode, ukwenzela ukuba indawo egudileyo ye-electrode coating ingaqhekeki.Ngokuqhelekileyo khetha i-elasticity ethile, imtyibilizi okanye i-absorbent emva kweempawu ezithile zokwandiswa kwemathiriyeli, njenge-mica, udaka olumhlophe, i-titanium dioxide, i-talc, iglasi yamanzi aqinileyo, i-cellulose, njl.

(5) I-arhente ye-alloy

Isetyenziselwa ukuhlawulela ukutshiswa kwezinto ezixutywayo kwinkqubo ye-welding kunye nokudlulisa izinto ze-alloying kwi-weld, ukwenzela ukuba kuqinisekiswe ukubunjwa kweekhemikhali kunye neempawu zentsimbi ye-weld.Ngokwesidingo sokukhetha iindidi zeferroalloys (ezifana neferromanganese, ferrosilicon, ferrochrome, iron and steel, ferric vanadium, ferric niobium, ferric boron, rare earth ferrosilicon, njl. , umgubo we-nickel, umgubo we-tungsten, njl.).

(6) I-arhente yokwenza i-slag

Ukuwelda kunokwenza iipropati ezithile zomzimba kunye neekhemikhali ze-slag etyhidiweyo, ukukhusela i-welding droplet kunye nesinyithi esityhidiweyo se-weld, ukuphucula ukubunjwa kwe-weld, njenge-agent ye-slagging yezinto eziluhlaza ziyi-marble, i-fluorite, i-dolomite, i-magnesia, i-feldspar, udaka olumhlophe, i-mica, i-quartz. , irutile, i-titanium dioxide, i-ilmenite, njl.

(7) Isidibanisi

Izinto zokugqoka ziboshwe ngokuqinileyo kwi-welding core, kwaye i-electrode coating inamandla athile emva kokumisa.Kwinkqubo ye-welding metallurgy, akukho mpembelelo iyingozi kwi-weld pool kunye nentsimbi ye-weld.Izibophelelo ezisetyenziswa ngokuqhelekileyo ziyi-sodium silicate (i-potassium, i-sodium kunye ne-sodium silicate edibeneyo) kunye ne-phenolic resin, i-gum, njl.

Ixesha lokuposa: May-04-2023