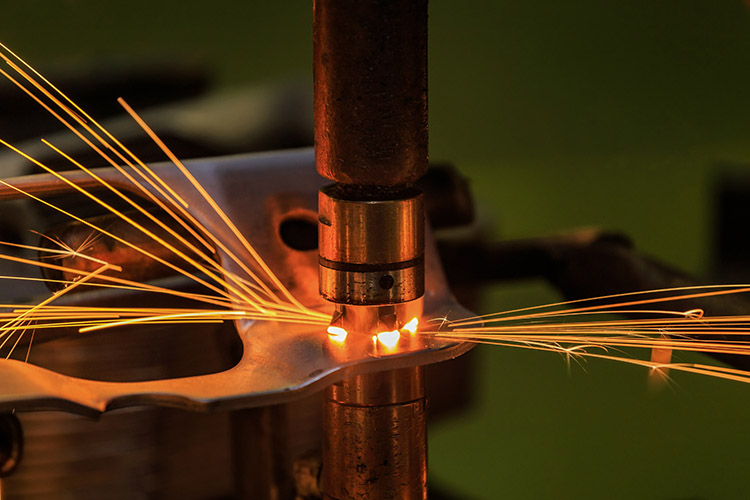

I-Spot welding yindlela yokumelana ne-welding apho i-weldment idityaniswe kwi-lap joint kwaye icinezelwe phakathi kwee-electrode ezimbini, kwaye isiseko sesinyithi sinyibilika ngokuxhathisa ubushushu ukwenza i-solder joint.

I-Spot welding isetyenziswa kakhulu kule miba ilandelayo:

1. Ilap joint ye sheet sheets stamping parts, ezifana ne-automobile cab, carriage, fish scale screen of harvester, njl.

2. I-Thin plate kunye necandelo lezakhiwo zetsimbi kunye nezakhiwo zesikhumba, ezifana neendonga zecala kunye neesilingi zeekhareji, iipaneli ze-trailer compartment panels, ukudibanisa iifuneli zokuvuna, njl.

3. Izikrini, iifreyimu zendawo kunye nemivalo enqamlezayo, njl.

Ci-haracteristic

Ngexesha le-welding, i-weldment yenza i-lap joint kwaye icinezelwe phakathi kwee-electrode ezimbini.Iimpawu zayo eziphambili zezi zilandelayo:

1. Ixesha lokufudumeza kwendawo yokudibanisa lifutshane kakhulu ngexesha lokudibanisa indawo, kwaye isantya se-welding sikhawuleza.

2. I-Spot welding idla kuphela amandla ombane, kwaye ayifuni izinto zokuzalisa okanye i-flux, igesi, njl.

3. Umgangatho wokuwelda indawo uqinisekiswa ikakhulu ngumatshini wokuwelda.Umsebenzi ulula, iqondo lomatshini kunye ne-automation liphezulu, kwaye imveliso iphezulu.

4. Amandla aphantsi abasebenzi kunye neemeko ezilungileyo zokusebenza.

5. Ekubeni i-welding energization igqitywe ngexesha elifutshane, i-current enkulu kunye noxinzelelo luyafuneka, ngoko ke inkqubo yokulawula inkqubo inzima kakhulu, umatshini we-welding unomthamo omkhulu, kwaye ixabiso lezixhobo lilinganiselwe. phezulu.

I-6.Kunzima ukwenza uvavanyo olungonakalisi kumalungu e-solder.

Inkqubo yokusebenza

Umphezulu we-workpiece kufuneka ucocwe ngaphambi kokuba udibanise.Indlela yokucoca esetyenziswa ngokuqhelekileyo kukucoca ukucoca, oko kukuthi, ukuthabatha kwi-asidi ye-sulfuric evuthayo kunye ne-concentration ye-10%, kwaye emva koko uhlambe emanzini ashushu.Inkqubo ethile yokuwelda imi ngolu hlobo lulandelayo:

(1) Thumela i-workpiece joint phakathi kwe-electrode ephezulu nangaphantsi yomatshini we-welding kwaye uyibambe;

(2) ukufakelwa kombane, ukwenzela ukuba iindawo zokudibanisa zezinto ezimbini zokusebenza zifudunyezwe kwaye zincibilike ngokuyinxenye ukwenza i-nugget;

(3) Gcina uxinzelelo emva kokuba umbane ucinyiwe, ukwenzela ukuba i-nugget ipholile kwaye iqiniswe phantsi koxinzelelo ukwenza i-solder joint;

(4) Susa uxinzelelo kwaye ukhuphe i-workpiece.

Imiba enempembelelo

Izinto eziphambili ezichaphazela umgangatho we-welding yi-welding yangoku kunye nexesha lokunika amandla, uxinzelelo lwe-electrode kunye ne-shunt, njl.

1. I-Welding yangoku kunye nexesha lamandla

Ngokobungakanani bexesha le-welding kunye nobude bexesha lokunika amandla, i-spot welding inokwahlulwa ibe ziindidi ezimbini: ukucaciswa okuqinileyo kunye nokucaciswa okuthambileyo.Inkcazo edlula umsinga omkhulu ngexesha elifutshane libizwa ngokuba yinkcazo enzima.Ineenzuzo zemveliso ephezulu, ubomi obude be-electrode, kunye ne-deformation encinci ye-weldment.Ifanelekile kwi-welding metals kunye ne-thermal conductivity engcono.Inkcazo edlula i-current encinci ixesha elide ibizwa ngokuba yi-soft specifikationer, enemveliso ephantsi kwaye ifanelekile kwiintsimbi ze-welding ezivame ukuba lukhuni.

2. Uxinzelelo lwe-electrode

Ngexesha le-welding yendawo, uxinzelelo olwenziwa yi-electrode kwi-weldment ibizwa ngokuba yi-electrode pressure.Uxinzelelo lwe-electrode kufuneka lukhethwe ngokufanelekileyo.Xa uxinzelelo luphezulu, i-shrinkage porosity kunye ne-shrinkage cavity enokuthi yenzeke xa i-nugget iqina inokupheliswa, kodwa ukuxhathisa uxhulumaniso kunye nokuncipha koxinzelelo lwangoku, okukhokelela ekufudumeni okwaneleyo kwe-weldment kunye nokuncipha kobubanzi be-nugget ye-nugget. i-solder joint.Amandla okudibanisa i-solder ayancipha.Ubungakanani boxinzelelo lwe-electrode bunokukhethwa ngokwezi zinto zilandelayo:

(1) Izinto ze-weldment.Ukuphakama kwamandla aphezulu obushushu bezinto eziphathekayo.Uxinzelelo olukhulu lwe-electrode olufunekayo.Ngoko ke, xa welding intsimbi stainless kunye nobushushu-resistant, uxinzelelo electrode kufuneka ibe phezulu kunolo low carbon steel.

(2) Iiparamitha ze-Welding.Okukhona kunzima ukucaciswa kwe-weld, ngakumbi uxinzelelo lwe-electrode.

3. shunt

Ngexesha le-welding yendawo, i-current ephuma ngaphandle kwe-welding main circuit ibizwa ngokuba yi-shunt.I-shunt inciphisa i-current ejikelezayo kwindawo ye-welding, okubangelwa ukufudumeza okunganeleyo, okubangelwa ukuhla okukhulu kwamandla e-solder joint kunye nokuchaphazela umgangatho we-welding.Imiba echaphazela iqondo loluleko ikakhulu ibandakanya le miba ilandelayo:

(1) Ubukhulu bentsimbi yentsimbi kunye nesithuba seendawo ezidityanisiweyo.Njengoko umgama phakathi kwamalungu e-solder ukhula, ukuxhathisa kwe-shunt kuyanda kwaye iqondo le-shunt liyancipha.Xa i-dot pitch yesiqhelo ye-30-50mm yamkelwe, i-shunt yangoku i-akhawunti ye-25% -40% yangoku iyonke, kwaye njengoko ubukhulu be-weldment buyancipha, i-degree of shunt nayo iyancipha.

(2) Ubume bomphezulu we-weldment.Xa kukho i-oxides okanye ukungcola ebusweni be-weldment, ukuchasana koqhagamshelwano phakathi kwee-weldments ezimbini kwanda, kwaye i-current ngokusebenzisa indawo ye-welding iyancipha, oko kukuthi, i-degree of shunt iyanda.I-workpiece ingakhethwa, ifakwe isanti okanye ipolishwe.

ImiGaqo yoKhuseleko

(1) Ukutshintsha kweenyawo kumatshini wokuwelda kufuneka kube nesikhuselo esiqinileyo sokukhusela ukuthintela ukusebenza ngengozi.

(2) Indawo yokusebenza iya kuxhotyiswa nge-baffle ukukhusela ukutshiza kweentlantsi ezisebenzayo.

(3) Abashicileli bafanele banxibe iindondo ezisicaba zokuzikhusela xa bewelda.

(4) Indawo apho umatshini welding ibekwe kufuneka igcinwe yomile, kwaye umhlaba kufuneka ugutyungelwe ngamabhodi achasene ne-skid.

5Xa iqondo lobushushu lisezantsi, amanzi aqokelelweyo kumzila wamanzi kufuneka asuswe ukuze kuthintelwe umkhenkce.

Ixesha lokuposa: Jul-31-2023