Yintoni ii-arc welding ene-flux-cored?

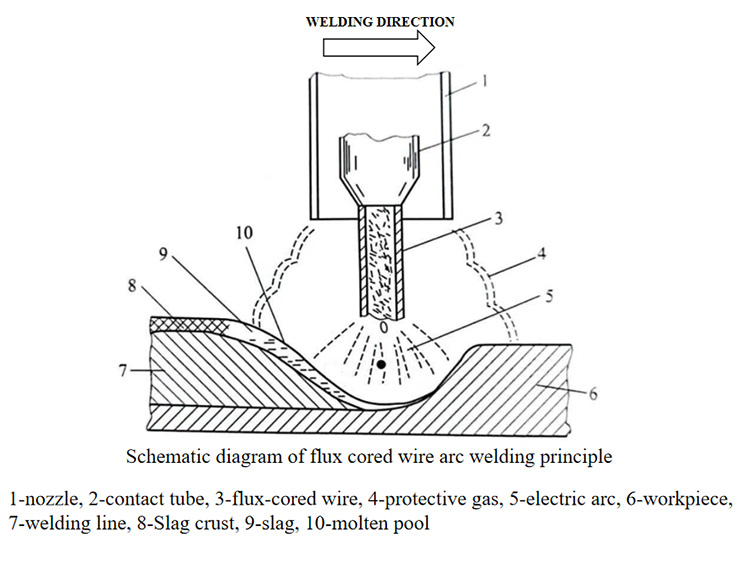

I-Flux-cored wire arc welding yindlela yokuwelda esebenzisa i-arc phakathi kwe-flux-coreed wire kunye ne-workpiece ukutshisa, kwaye igama layo lesiNgesi yi-FCAW ngokulula.Ngaphantsi kwesenzo sobushushu be-arc, i-welding wire metal kunye ne-workpiece idibaniswe ngokunyibilika, ukwenza i-pool ye-weld, i-arc phambili emva kwe-crystallization yomsila we-weld pool.

Yintoni ucingo olune-flux-cored?Ziziphi iimpawu zekhatriji?

I-Flux-cored welding wire luhlobo lwe-welding wire eyenziwa ngokuqengqeleka umcu obhityileyo wentsimbi kumbhobho wentsimbi okanye umbhobho wentsimbi owenziwe ngendlela ekhethekileyo, uzalise umbhobho ngamacandelo athile omgubo, kunye nomzobo.Ukubunjwa kwepowder core kufana ne-electrode coating, eyona nto iqulethwe yi-arc stabilizing agent, i-slag forming agent, i-gas forming agent, i-alloying agent, i-deoxidizing agent, njl.

Iyintoni indima yolusuko kucingo olune-flux-core?

Indima ye-flux ifana ne-electrode coating, kwaye kukho ubukhulu becala ezi ntlobo zilandelayo.

① Isiphumo esikhuselayo samanye amacandelo ekuboleni kwe-welding flux, okunye ukunyibilika!Ukubola kwe-welding flux ikhupha igesi, enika enye okanye ukhuseleko oluninzi.I-flux etyhidiweyo yenza i-slag etyhidiweyo, egubungela umphezulu we-droplet kunye ne-pool etyhidiweyo, kwaye isinyithi esimanzi siyayikhusela.

② I-arc stabilizer kwi-arc stabilizer cartridge inokuzinzisa i-arc kunye nokunciphisa izinga lokutshiza.

③ Isenzo somdibaniso Ezinye zeziqalelo zengxubevange kumbindi zinokudibanisa i weld.

④ Izinto ze-deoxidation zealloy ze-slag zinokusabela ngeentsimbi ezingamanzi.Ukuphucula ukubunjwa kwentsimbi ye-weld, ukuphucula iimpawu zayo zomatshini.

Ukongeza, i-slag egqunyiweyo inokunciphisa izinga lokupholisa kwi-pool etyhidiweyo, yandise ixesha lobukho be-pool etyhidiweyo, enenzuzo ekunciphiseni umxholo wegesi enobungozi kwi-weld kunye nokukhusela i-porosity.

Zeziphi iintlobo ze-flux cored arc welding ezikhoyo?

Kukho iintlobo ezimbini ze-flux cored wire arc welding (FCAW-G) kunye ne-self-protection welding (FCAW-S), kuxhomekeke ekubeni igesi yokukhusela yangaphandle isetyenzisiweyo okanye cha.

Irhasi ekhuselweyo ukuwelda yocingo olunamacingo ahambayo ngokuqhelekileyo isebenzisa ikharbon diokside okanye i-carbon dioxide kunye ne-argon njengegesi ekhuselayo, kunye nokuhamba kocingo kuqulethe i-agent encinci yegesi.Le ndlela ifana ne-welding jikelele yegesi ekhuselekileyo.I-welding yokuzikhusela ayifuni igesi yokukhusela yangaphandle.Kukho inani elikhulu le-gasifier kwi-flux, kwaye i-gas kunye ne-slag echithwa yi-gasifier isetyenziselwa ukukhusela.

Zeziphi iingenelo ze-flux-cored arc welding?

I-Flux-cored arc welding ineenzuzo ezilandelayo.

(1) Imveliso ye-welding ephezulu yokunyibilika okuphezulu (ukuya kuma-85% ~ 90%), isantya sokunyibilika ngokukhawuleza;Ukuwelda flat, isantya ukutyabeka amaxesha 1.5 ukuba manual arc welding, kunye nezinye izikhundla welding, yi 3-5 amaxesha ukuba manual arc welding.

② Ukuchaphaza okuncinci, i-weld yenza isiseko sechiza esilungileyo songeze i-arc stabilizer, ngoko ke uzinzo lwe-arc, ukuchaphaza okuncinci, ukwenza i-weld elungileyo.Ngenxa yokuba idama elityhidiweyo ligqunywe nge-slag etyhidiweyo, ukumila komphezulu we-weld kungcono kakhulu kunoko welding ye-carbon dioxide.

(3) Umgangatho ophezulu we-welding Ngenxa yegesi ye-slag edibeneyo yokukhusela, inokuthintela ngokufanelekileyo igesi eyingozi ukuba ingene kwindawo ye-welding.Ukongeza, ixesha lobukho bechibi elinyibilikisiweyo lide, elivumela ukuna kwerhasi, ngoko ke i-weld inomxholo ophantsi we-hydrogen kunye nokuxhathisa okulungileyo kwe-porosity.

(4) Ukulungelelaniswa okuqinileyo kufuna kuphela ukulungelelanisa ukubunjwa kwe-solder wire cored, inokuhlangabezana neemfuno zeentsimbi ezahlukeneyo kwi-weld composition.

Ziziphi izinto ezingeloncedo nge-arc welding ye-flux-cored?

Iintsilelo ze-flux-cored arc welding zilandelayo.

Xa kuthelekiswa ne-gas shielded welding, ixabiso le-welding wire liphezulu kwaye inkqubo yokuvelisa inzima.

② Ukutya ngocingo kunzima, kuyimfuneko ukusebenzisa umatshini wokutyisa ucingo oxinzelelo lwe-clamping lunokulungelelaniswa ngokuchanekileyo.

③ I-cartridge kulula ukufunxa ukufuma, ngoko ke kuyimfuneko ukugcina ucingo lwe-welding ngokungqongqo.

④ Ukususwa kwe-slag kuyadingeka emva kwe-welding.

⑤ Umsi omninzi kunye neegesi ezinobungozi ziveliswa kwinkqubo ye-welding, ngoko ke umoya kufuneka uqiniswe.

Yeyiphi igesi ekhuselayo edla ngokusetyenziswa kwi-flux-cored arc welding?Ziziphi iimpawu zento nganye?

I-Flux cored wire arc welding ngokuqhelekileyo isebenzisa igesi ye-carbon dioxide ecocekileyo okanye i-carbon dioxide kunye negesi ye-argon njengegesi ekhuselayo.Uhlobo lwegesi kufuneka lukhethwe ngokwe-flux-core wire esetyenzisiweyo.

I-Argon i-ionized ngokulula, ngoko kulula ukufezekisa utshintsho lwe-ejection kwi-argon arc.Xa umxholo we-argon womxube wegesi ungekho ngaphantsi kwe-75%, i-flux cored wire arc welding inokufezekisa utshintsho oluzinzileyo lwe-jet.Ngokuhla komxholo we-argon, ubunzulu bokungena buyanda, kodwa ukuzinza kwe-arc kuyancipha kwaye izinga lokutshiza liyanda.Ngoko ke, oyena mxube werhasi yi-75% Ar+25% CO2.Ukongeza, i-Ar+2% O2 ingasetyenziselwa umxube werhasi.

Xa igesi ye-CO2 ecocekileyo ikhethiweyo, iya kubola phantsi kwesenzo sobushushu be-arc kwaye ivelise inani elikhulu lee-athomu ze-oksijini, eziza kwenza i-manganese, i-silicon kunye nezinye izinto kwi-pool etyhidiweyo, ekhokelela ekutshisweni kwezinto ezixutywayo.Ke ngoko, i-welding wire kunye ne-manganese ephezulu kunye nomxholo we-silicon kufuneka isetyenziswe.

Ixesha lokuposa: May-09-2023